Agellis®

Tellusgatan 15

22457 Lund

Sweden

Our main “Nonferrous” solutions are reliable systems for metal level measurement in smelter furnaces. We supply both, online metal level systems and unique furnace material profile systems, to accurately define the different furnace levels on-demand.

Additionally, the portfolio consists of solutions allowing process control and operational safety.

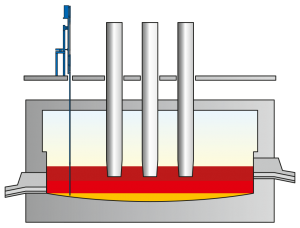

The EMLI-SmelterLevel system continuously measures the true metal level in smelters/furnaces where real-time accurate monitoring is required. The system does this irrespective of metal type, amounts of slag on top of the metal, required measurement range and temperature.

With cover protected sensors mounted behind the furnace refractory lining and positioned to span the required measurement range, the systems provides information to continuously track metal levels during melting and tapping processes. High and low levels are all indicated, tracked and displayed. The sensors are designed to operate reliably in the harsh conditions for the full furnace refractory campaign.

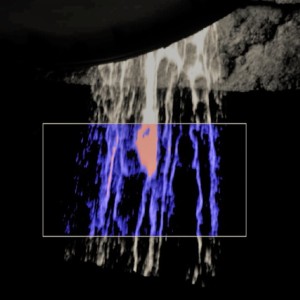

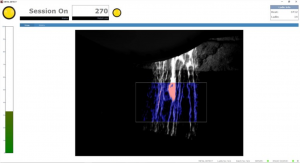

The EMLI-FurnaceProfile system is a measurement unit that records a complete material level/profile at a fixed location point in a furnace whenever required. The measurement method used is based on a patent pending technology. The system is used in all furnace/smelter types where access is possible and the process requires knowledge of different material levels.

Slag thickness, matte level and bottom build-up can all be provided quickly and easily with a semi-automatic delivery system. The operator is in a safe place during the entire operation minimising the risks often seen with manual level measurements. It is even possible to combine the EMLI-FurnaceProfile with temperature and material sampling. The sensors used are not consumable items and will continue to provide measurement for many sequences. We provide several types of delivery system, vertical entry, tilt or swing arm entry, as well as complex custom made solutions.

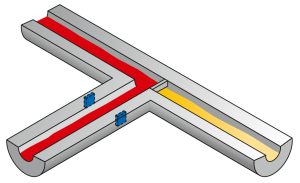

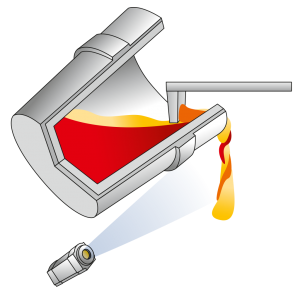

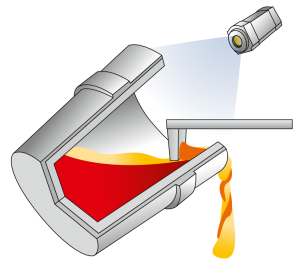

The EMLI-MetalSlag continuously monitors the metal flow during tapping of the furnace and provides alarm outputs at the onset of slag in the stream. These outputs can be used to immediately end tapping by gate closure or by change of tilt angle, while also giving visual and audible alarms.

Sensors/cabling are customized to fit any furnace and sliding gate/tap-hole arrangement with only minimal modification to existing equipment. The Management Unit is capable of running multiple Control Units of the same or different EMLI system types. This enables the user to expand the system to run extra slag detection systems or add mould level or tundish level measurement systems. Plant tested components make the EMLI System extremely durable with low maintenance costs. All EMLI systems have compatible parts, that means stocking spares is also simple and cost effective.

Iron making blast type furnaces as well as SAF, Flash, Peirce Smith, Reverberatory, Teniente and Slag Cleaning Furnaces and others can all benefit from use of the EMLI-MetalSlag system.

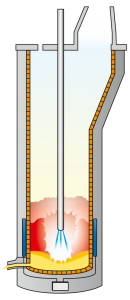

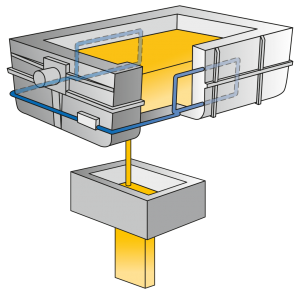

EMLI-TundishLevel provides the operator with extremely sensitive measurement of the true steel level in a continuous casting tundish, irrespective of the amount of slag or powder present.

With a measurement range over the full depth of the tundish, the operator will always have precise information about the steel level, be able to maintain the correct pressure head and also to drain the tundish while preventing slag carryover to the mould, thus increasing yield. Individual tundish identification assists system function and improves customer process control. Automatic calibration, high & low level alarms, self-diagnostics, multiple input/output options and continuous data logging, enable the system to be compatible with all customer operating procedures and control requirements.

Plant tested components make the EMLI system extremely durable with low maintenance costs. Sensors are mounted against the inside wall of the tundish, are cover protected and sensor tails exit through compression fittings to heavy duty connectors on the outside. The sensors require no special handling or cooling and are able to run at 900 °C continuously while resisting chemical corrosion.

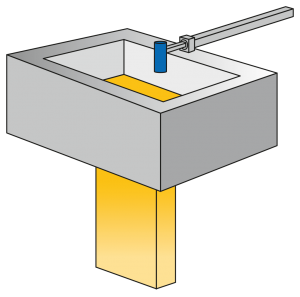

The EMLI-MouldLevel Suspended sensor continuously monitors metal level in the mould during casting and provides outputs to control the flow to maintain desired operating levels.

EMLI-MouldLevel Suspended is the most advanced electromagnetic mould level measurement system available on the market. It is exceptionally accurate and reliable. The flexible electronics platform ensures an easy installation and a wide array of options is available. The automatic calibration rig performs a full 21 point calibration in a matter of a few minutes, making sure that maintenance procedures demand a minimum of resources and can be performed in a very short period of time.

The user friendly software allows easy access to running information at all times from the Control room or any other desired service access point using LAN access. Agellis offers two types of suspended sensors, a thin 40mm diameter and a larger 90mm diameter sensor making sure the mould level system can be used with optimal performance in most bloom and slab formats.

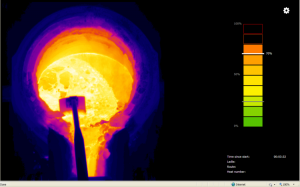

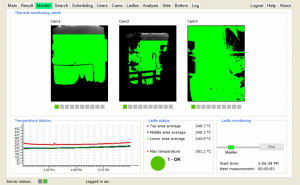

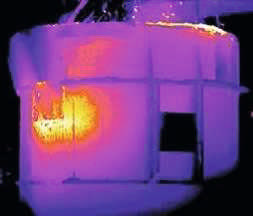

The VISIR-FurnaceSafe infrared monitoring of your furnace shell minimises the risk of liquid metal breakout and maximises your operational furnace availability while at the same time increasing safety.

The risk of a breakouts will always be present when handling liquid metal with equipment damage, personnel injuries and loss of production as the consequence.

VISIR-FurnaceSafe continuously monitors the furnace shell thermal status and trends temperatures covering over 100 000 measuring points.

The monitoring system automatically alerts you when detecting early signs of dangerous hot spots, helping you to handle the situation before it becomes a hazard.

FurnaceSafe stores data in a measurement database, letting you create weekly reports and evaluate refractory performance.

The risk of a ladle breakout will always be present in steelmaking with equipment damage and loss of production as the costly consequences. Your production and operation routines could minimise this risk, but the fact remains; as long as liquid steel is transported using ladles – ladle breakouts will occur from time to time.

Are you constantly concerned about the potential risks of metal breakouts?

Are you feeling that your ladle refractories sometimes could last a few more heats, but you must think of safety first?

Would you feel more confident in pushing the ladle refractory lifetime if a system scanned every ladle before it was sent to the casting bay?

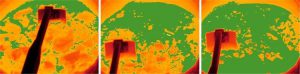

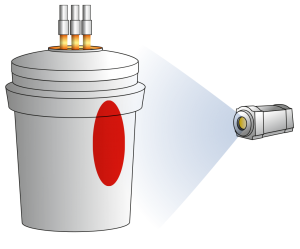

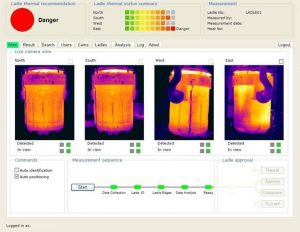

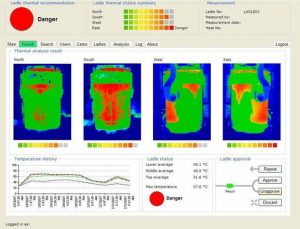

If the answer to any of the above is YES, VISIR-LadleSafe is what you are looking for. VISIR-LadleSafe is based on infrared camera technology using data analysis to evaluate the steel structure thermal status of your ladles.

The crane operator positions the ladle in the measurement position which is usually located at the end of the liquid metal processing stage, just prior to reaching the casting bay. He ensures that all sides of the ladle are inside the field of view of the thermal cameras.

Once the ladle is in position, the crane operator starts the measurement by the use of a touch screen monitor. The system reads the ladle I.D, performs a few checks, and then starts taking thermal data used for the analysis. Typically the analysis result of the thermal status is returned to the crane operator within seconds. The result is summarized in a recommendation which assists the crane operator in tracking down dangerous ladles. Based on the analysis results the operator decides if the ladle is safe to continue using.

The operator is also given the opportunity to study some parts of the ladle analysis in detail, as well as study a graphical display of the previous measurement results of the same ladle.

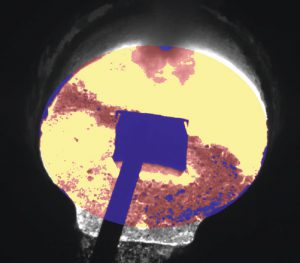

The VISIR-MetalDetect improves your metal yield through detection and control of metal losses in the deslagging process.

The VISIR-MetalDetect system is designed to monitor the ladle or furnace deslagging operations in order to detect when metal is being poured. Thus a minimal amount of metal is lost and yield improved.

MetalDetect uses a thermal camera and vision technology in order to monitor the deslagging operations in real time.

By using the VISIR-MetalDetect system you will be able to assist operators to control their deslagging metal losses in a safe and secure manner. The thermal camera mounted behind the deslagging stream will monitor the process automatically and inform the operator when metal is detected so that they can modify the process quickly and safely.

By better control of the deslagging process variations and ensuring that the metal losses are significantly reduced, yield improvements and consistency can be achieved.

The VISIR-MetalDetect system will automatically track and store vital information for each heat and make sure your yield and quality assurance program is met every time.

The VISIR-LadleDeslag system monitors ladle skimming operations to help achieve clean ladle metal for further process operations, while at the same time ensuring that excessive metal loss is avoided. VISIR-LadleDeslag cameras and software evaluate the ladle surface slag content and feeds information to the operator when a sufficient skimming has been achieved.

Are you experiencing uncontrolled sulphur increases in the BOF? Are you experiencing uncontrolled reoxidation during ladle treatment? Do you feel a need to narrow down process variations in the final steps of processing? Do you see that the deslagging performance varies considerably from ladle to ladle and is operator dependent?

If you associate with any of the above, VISIR-LadleDeslag will assist you in solving your problem.

Carryover slag variations in ladles are often the cause of a number of problems detrimental to processing and product quality. Unforeseen reoxidation reduces alloying yields and refining efficiency forcing the operator to deviate from the standard processing and take additional processing steps. The added oxygen also contributes to the formation of non-metallic inclusions that lowers product quality.