对不起,此内容只适用于English。 For the sake of viewer convenience, the content is shown below in the alternative language. You may click the link to switch the active language.

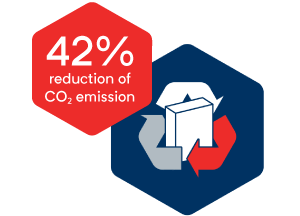

RADEX AF-LC stands for low carbon and refers to the significantly lower CO2 footprint compared to conventional refractory products. This is mainly achieved by using secondary recycled materials from kilns within a circular economy framework.

High quality standards can be maintained while significantly lowering CO2 emissions:

By using recycled material instead of primary the carbon footprint of the end product can be reduced by up to 42%.

By using recycled material instead of primary the carbon footprint of the end product can be reduced by up to 42%.

Introducing the benefits of RADEX AF-LC:

RADEX AF-LC is produced from high grade forsteritic magnesia and selected, locally available secondary raw materials. By using a forsteritic brick concept with a C/S ratio equal to approximately 0.5, RHI Magnesita made it possible to offer a brick concept that provides

- High performance product with excellent quality and reliability

- Reduction of CO2 emissions

- High corrosion resistance against sulfur containing fuels

- Conservation of primary raw materials

- Shortening of transport routes

- Excellent refractoriness in lime shaft kiln application

- High thermal shock resistance

Introducing the benefits of RADEX AF-LC:

- High performance product with excellent quality and reliability

- Reduction of CO2 emissions

- High corrosion resistance against sulfur containing fuels

- Conservation of primary raw materials

- Shortening of transport routes

- Excellent refractoriness in lime shaft kiln application

- High thermal shock resistance

With this development, we have proven that circular economy and maintaining high product quality can go hand in hand. Through close collaboration with our customers, as well as their commitment to support a circular economy approach, we can significantly reduce CO2 emissions.

Heinz Telser

Head of Sales Industrial Europe, CIS & Turkey

Please note that currently this product is only available for customers in Europe.

Please note that currently this product is only available for customers in Europe.

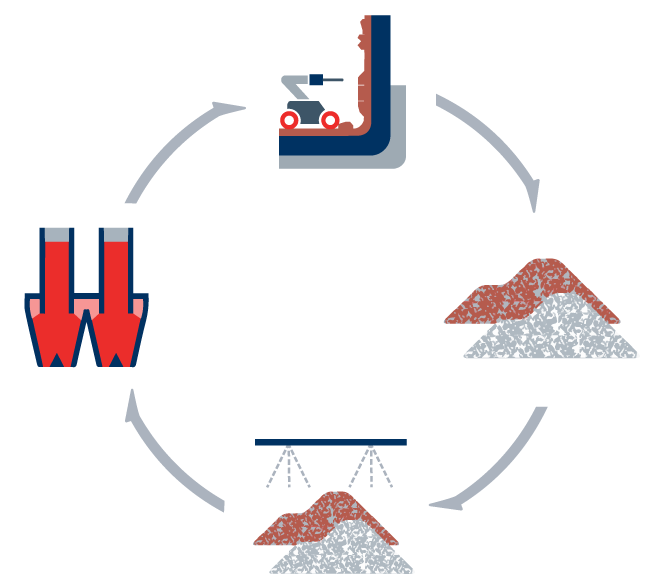

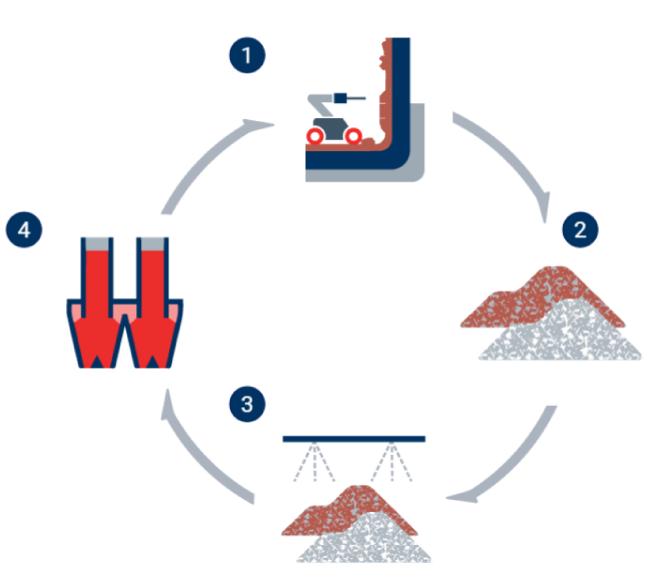

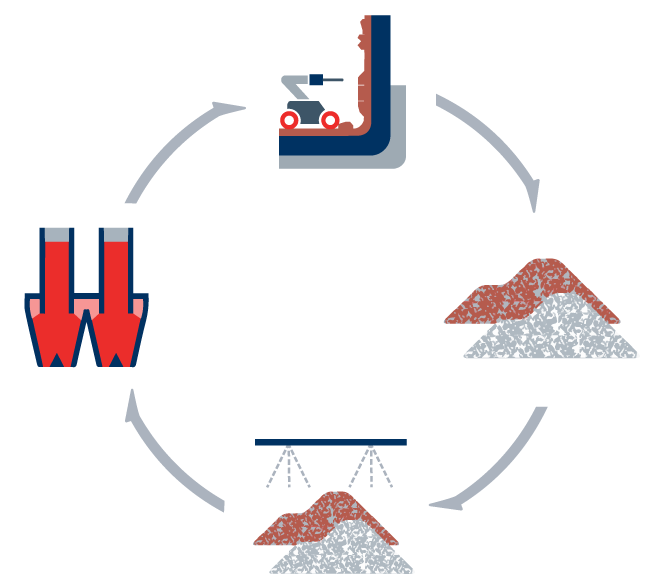

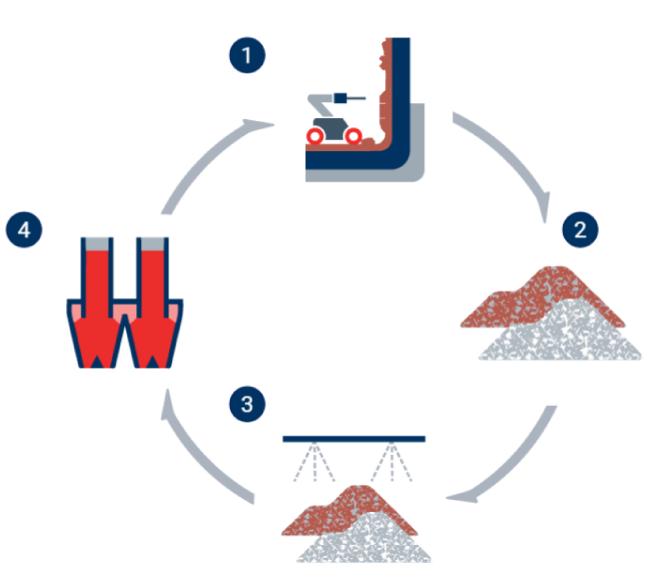

Discover the circular economy approach

Circular economy is the only effective approach to ensure sustainable use of raw materials. Collaboration is key for successful implementation as the process starts and ends in the customer kilns.

1

De-Bricking of lining

- residual lining material is removed in sections

- the material is transported out of the kiln

2

Sorting & Declaration

- Extraction & sorting

per category

- Temporary storage

- Declaration of waste

3

Reconditioning

- Sorted material will be

transported to the recycling hub.

- Final sorting & cleaning

- Patented treatment process

& end of waste declaration

- Production of LC series

4

Start & End of Production

- Installation of new lining

- Restart of kiln

- Sustainable lining

in operation

Discover how it works

Circular economy is the only most effective approach to ensure sustainable use of raw materials. Collaboration is key for successful implementation as the process starts and ends in the kilns of our customers.

1. De-Bricking of lining

- Residual lining material is removed in sections

- The material is transported out of the kiln

2. Sorting & Declaration:

- Extraction & sorting per category

- Temporary storage

- Declaration of waste

3. Reconditioning:

- Disposed material will be transported to the recycling hub.

- Final sorting & cleaning

- Patented treatment process & end of waste declaration

- Production of LC series

4. Start & End of Production

- Installation of new lining

- Restart of kiln

- Sustainable lining in operation

The circular economy approach – How it works

With this process the life cycle of raw materials can be increased by turning used refractory bricks into valuable source of raw materials at the end of their service life.

Kiln Shutdown

- Removal of coating & general inspection

- Breakout of used bricks & sorting per catgory

- Temporary storage & declaration of waste

- Installation of new lining

- Restart of kiln

Reconditioning Treatment

- RHI Magnesita purchase order for waste material

- Final set of documentation

- Final sorting & cleaning

- Patented treatment process & end of waste

- Quality control

Production & Delivery of LC Series

- Production of LC-Series brand

- Final quality check & packaging

- In-time delivery to client

Get more information

An expert dedicated to your area will get in touch with you.

![]()

![]()