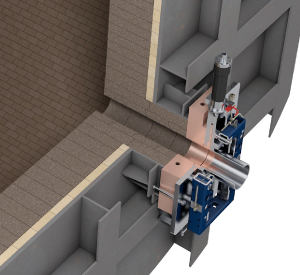

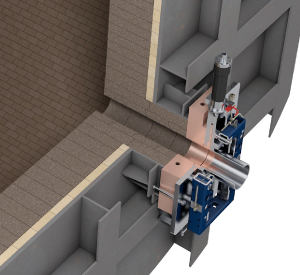

The S-TAP Slide Gate enables an accurate regulation of the slag tapping flow rate, integrating tap-hole design, systems, sensors and robotics in one solution. As such, you can improve your safety and productivity by minimizing slag splashing and prevent metal carryover via sensoric devices. An immediate emergency tap hole closing and state of the art robotic automation will allow you a reliable and safe operation.

Your benefits at a glance

- Accurately controlled and steady slag flow for each tapping condition or furnace type

- Regulated slag tapping rate for downstream process/vessel

- Compatible with other tapping equipment and devices

- Improved yield through optimal drain of the vessel

- Metal free tapping

- Simple, fast, and safe operation

Your benefits at a glance

- Accurately controlled and steady slag flow for each tapping condition or furnace type

- Regulated slag tapping rate for downstream process/vessel

- Compatible with other tapping equipment and devices

- Improved yield through optimal drain of the vessel

- Metal free tapping

- Simple, fast, and safe operation

Increased Safety Standard through

- Reduced manual handling work

- Rapid tap-hole closing

(e.g. in case of an emergency)

- Higher degree of automation

Increased Safety Standard through

- Reduced manual handling work

- Rapid tap-hole closing

(e.g. in case of an emergency)

- Higher degree of automation</li

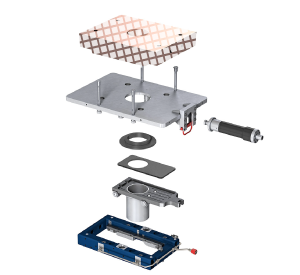

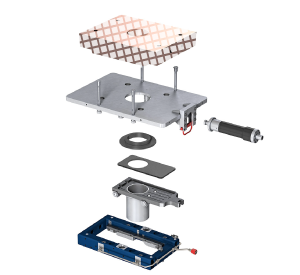

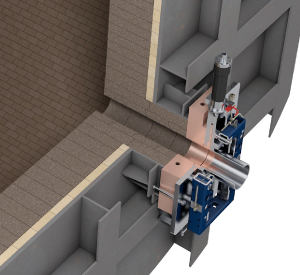

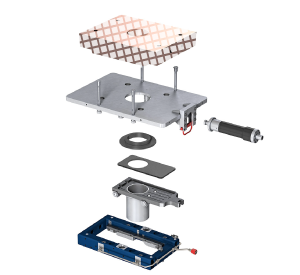

Core features

- One plate system

- Interface to copper block (or copper cooling element) of a tap-hole

- Fits onto almost any tap-hole design

- Automatic system tensioning

- High temperature resistant tension elements

- Only two main components: housing and slider

- Quick and simple exchange of the components

- Protection against slag splashes with heat shield

- Hydraulic units and tools and jigs available

- Easy integration of robotic system, sensor devices (Robotic process automation, EMLI)

- After sales service and low maintenance

Core features

- One plate system

- Interface with tap-hole copper block (or copper cooling element)

- Fits onto almost any tap-hole design

- Automatic system tensioning

- High temperature resistant tension elements

- Only two main components: housing and slider

- Quick and simple exchange of the components

- Protection against slag splashes with heat shield

- Hydraulic units and tools and jigs available

- Easy integration of robotic system, sensor devices (Robotic process automation, EMLI)

- After sales service and low maintenance

Add-on modules

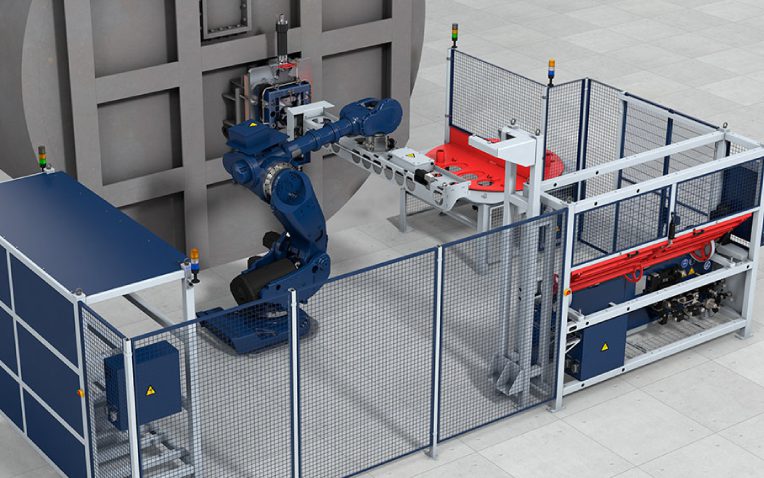

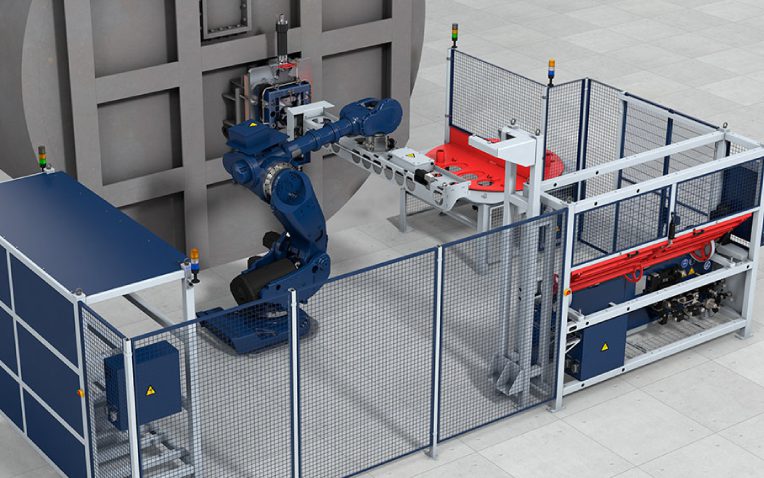

Robotic Process Automation

The taphole area is one of the areas with the highest safety concern. Our automated and remotely controlled tapping systems can increase safety by minimizing the presence of operators in the tap-hole area.

Benefits

- Increased safety for employees

- Reproducible quality level of tasks

- Prevention of breakthroughs by increasing process stability

- Reduction of production costs and efficiency through constant monitoring of system

- Integration of “smart” solutions for better planning of maintenance

- Entire life cycle for tapping systems & solutions

Core features

- Oxygen lancing of tap-hole channel

- Insert of a guide bar for lancing

- Optical measuring system

- Sample taking and temperature measurement

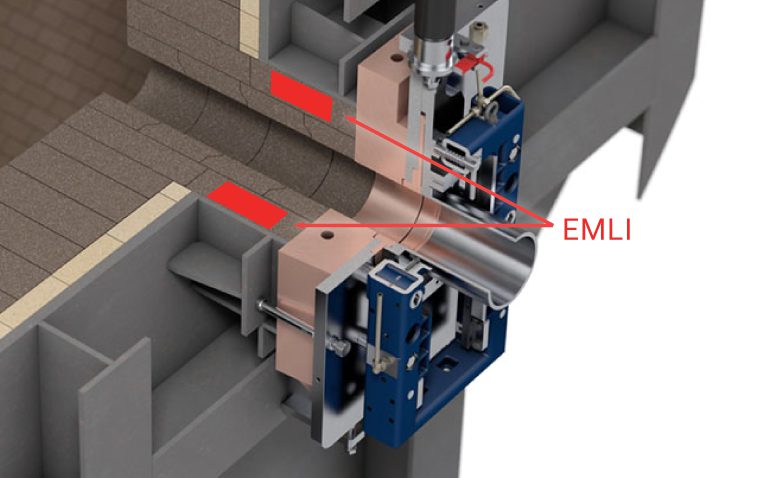

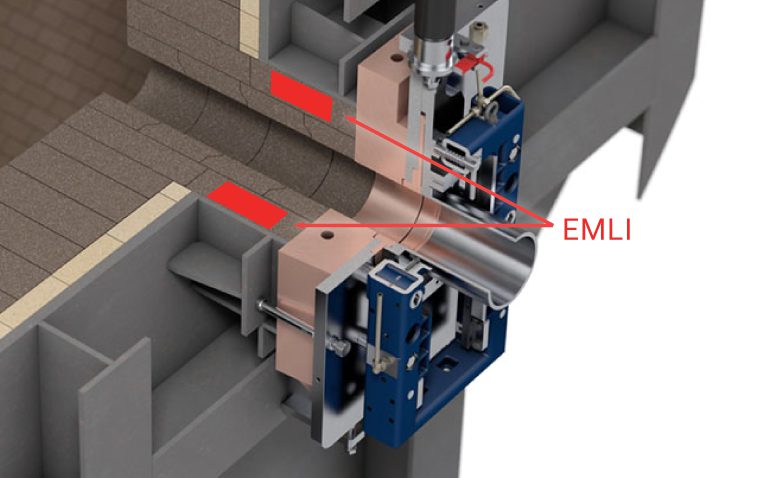

EMLI – Electromagnetic Metal detection system

The EMLI technology continuously monitors the slag flow during tapping of the furnace and provides alarm outputs at the onset of metal in the stream. These outputs can be used to immediately end tapping by gate closure, while also giving visual and audible alarms.

Benefits

- Control metal carryover precisely with a fast response time

This is very important when granulating slag with water, as the presence of metal in the slag can lead to violent explosions.

- Increase production yield by leaving minimal amounts of slag in the furnace

- Can handle any slag grades

Discover more about the EMLI solutions

Get in touch!

If you have any questions regarding the S-TAP Slide Gate, please do not hesitate to contact us. An expert will get in touch with you.

Discover also the COP FLOW Slide Gate – our solution for metal tapping.