Or even get rid of your old bricks? Give your bricks a second life and contact us for further information!

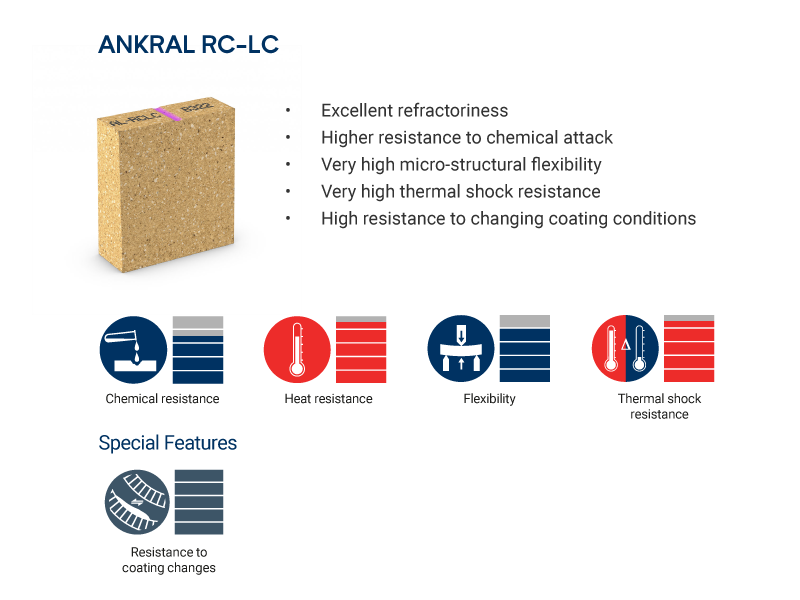

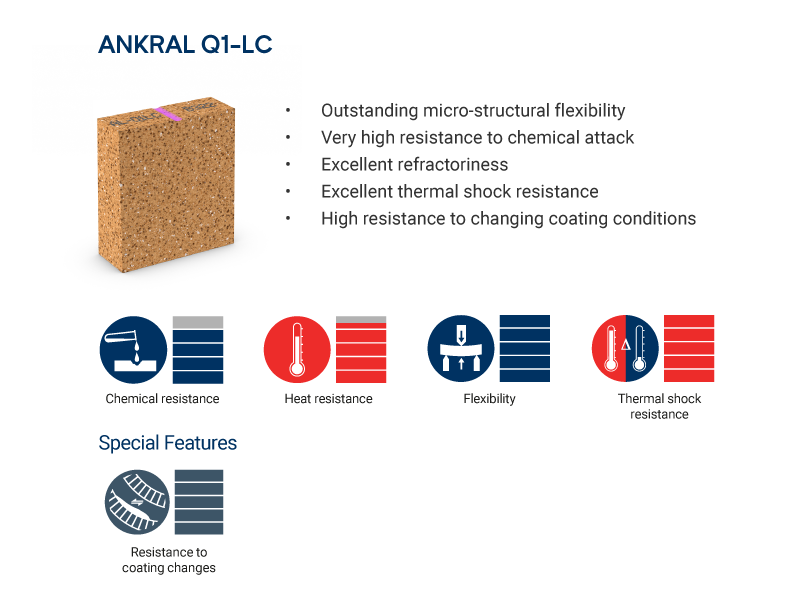

ANKRAL LC stands for low carbon and refers to the significantly lower CO2 footprint compared to conventional refractory products. This is mainly achieved by using secondary recycled materials from rotary cement kilns within a circular economy framework.

The ANKRAL LC Series is a high performance refractory product. It consists of a high amount of recycled raw material and as such, contributes to a reduced carbon footprint.

By using recycled material instead of primary Dead Burned Magnesia, the carbon footprint of the of the final product can be reduced by up to 14%.

By using recycled material instead of primary Dead Burned Magnesia, the carbon footprint of the of the final product can be reduced by up to 14%.

Dr. Christopher Ehrenberg

Plant manager of Lafarge Zementwerk Mannersdorf

Source: Pressrelease: Sustainability rocks

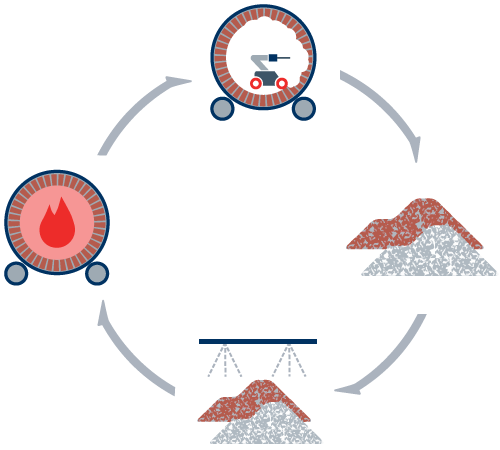

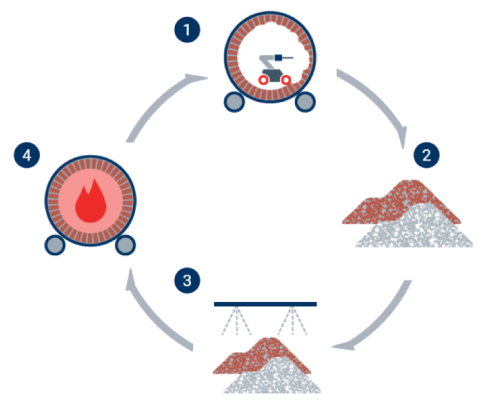

The circular economy approach is a process that starts and ends your kilns. It increases the lifecycle of our products by turning used refractory bricks at the end of their service life into a valuable raw material source.

We designed a process in order to increase the lifecycle of our products.

Discover in 4 easy steps how this practice increases the lifespan of the refractory lining:

1. De-bricking: After the stop of the kiln, it gets inspected and the material is dismantled.

2. Sorting & Declaration:

3. Reconditioning:

4. Start & End of Production

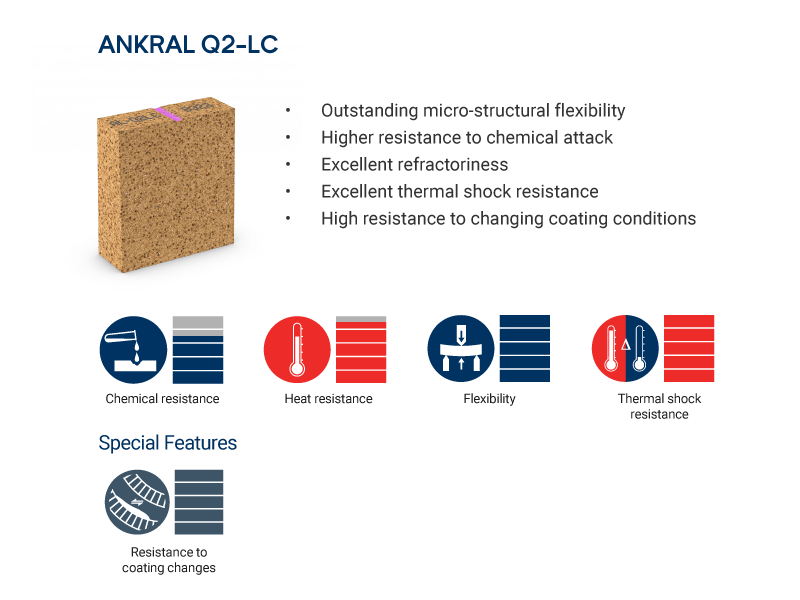

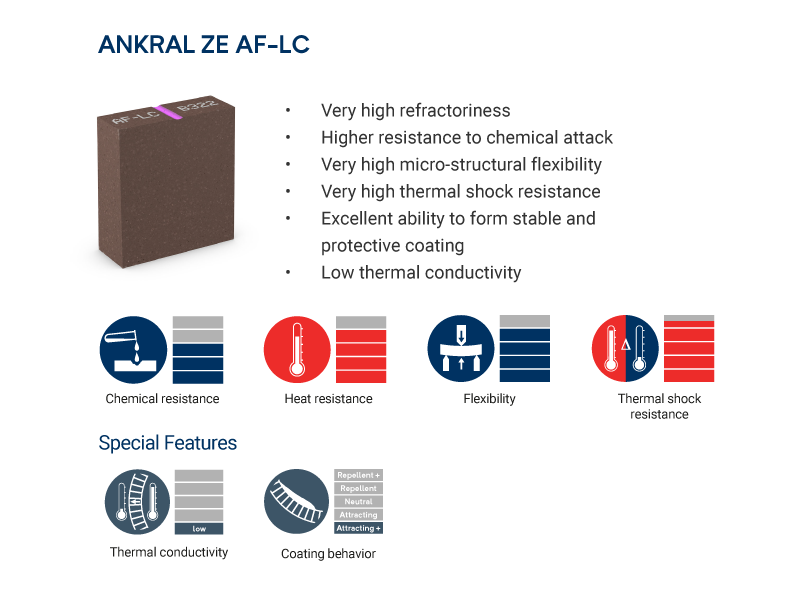

The LC-series product portfolio currently consists of four products for application under different operational conditions.

An expert dedicated to your area will get in touch with you.