The market launch of the new INTERSTOP® SX ladle gate has begun recently. Customers who already use the new INTERSTOP® SX ladle gate benefit from the following main advantages:

The market launch of the new INTERSTOP® SX ladle gate has begun recently. Customers who already use the new INTERSTOP® SX ladle gate benefit from the following main advantages:

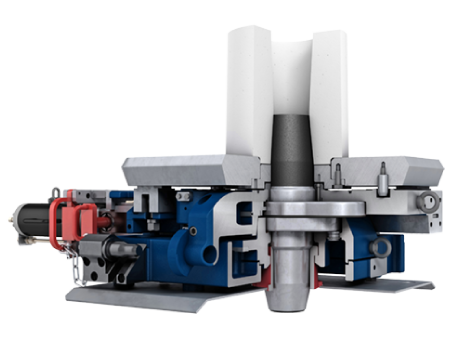

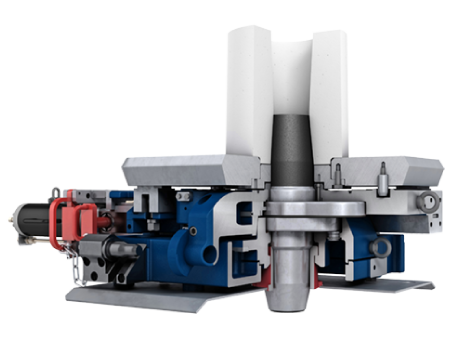

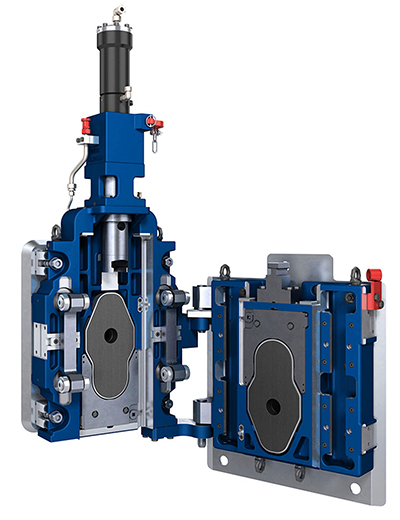

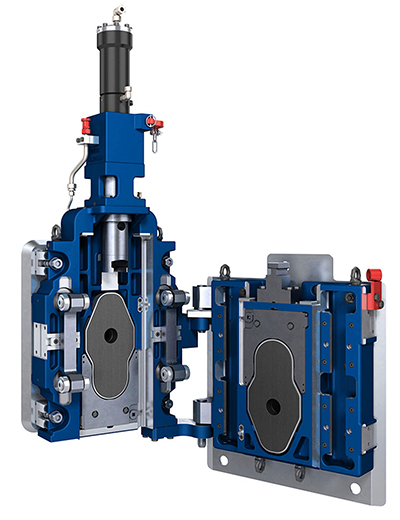

The new INTERSTOP® ladle gate Type SX is a high-performance ladle gate system focused on optimising total cost of ownership (TCO) as well as safe and easy operation. The advanced refractory concept is leading to improved efficiency. The smart handling characteristics allow for easy and safe operation and are incorporated within a maintenance-friendly design.

The new development has a positive impact on the overall operating costs and increases the safety standard during handling and operation.

Moreover, the new SX type gate provides the possibility to perform an “open check”, a feature allowing the personnel in the ladle preparation area to assess the refractory plates condition more reliably. This unique extra feature is outlined in the following sections.

The new INTERSTOP® ladle gate Type SX is a high-performance ladle gate system focused on optimising total cost of ownership (TCO) as well as safe and easy operation. The advanced refractory concept is leading to improved efficiency. The smart handling characteristics allow for easy and safe operation and are incorporated within a maintenance-friendly design.

The new development has a positive impact on the overall operating costs and increases the safety standard during handling and operation.

Moreover, the new SX type gate provides the possibility to perform an “open check”, a feature allowing the personnel in the ladle preparation area to assess the refractory plates condition more reliably. This unique extra feature is outlined in the following sections.

System reliability and availability are the most important objectives in operating a ladle slide gate system. When this is achieved, improved safety is the consequence. In addition to this, optimising operating costs and the focus to improve the TCO is a continuing demand.

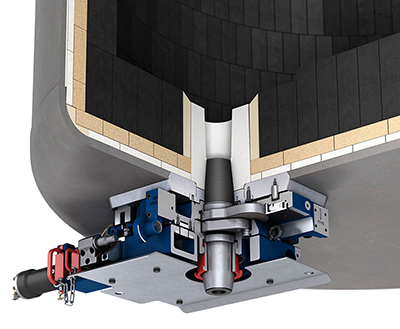

The new “open-check” feature of the INTERSTOP® SX gate system results in optimising the specific operating costs without increasing the risk for failure.

Benefit of the “Open-Check”:

The purpose of the “open-check” procedure is to increase the plate lifetime by minimizing the risk for infiltration.

System reliability and availability are the most important objectives in operating a ladle slide gate system. When this is achieved, improved safety is the consequence. In addition to this, optimising operating costs and the focus to improve the TCO is a continuing demand.

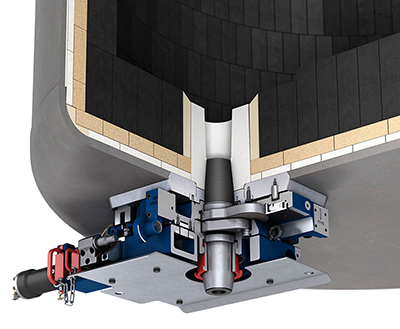

The new “open-check” feature of the INTERSTOP® SX gate system results in optimising the specific operating costs without increasing the risk for failure.

Benefit of the “Open-Check”:

The purpose of the “open-check” procedure is to increase the plate lifetime by minimizing the risk for infiltration.

![]()

The “open-check” increases the safety standard, as it supports the preparation workers in the decision to proceed with one additional heat. The plate condition can be properly assessed by having a direct view on the refractory plate surfaces.

![]()

The “open-check” increases the safety standard, as it supports the preparation workers in the decision to proceed with one additional heat. The plate condition can be properly assessed by having a direct view on the refractory plate surfaces.

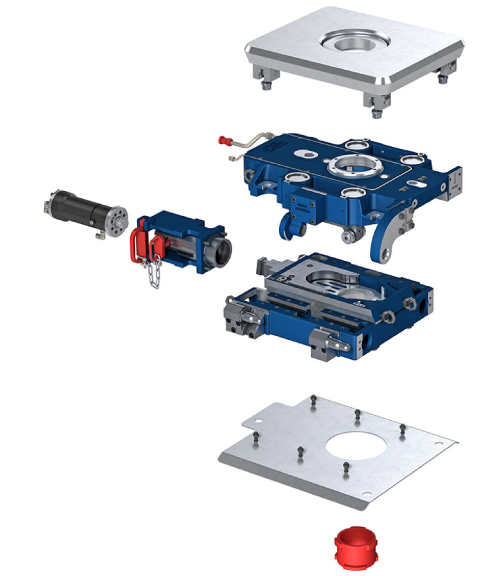

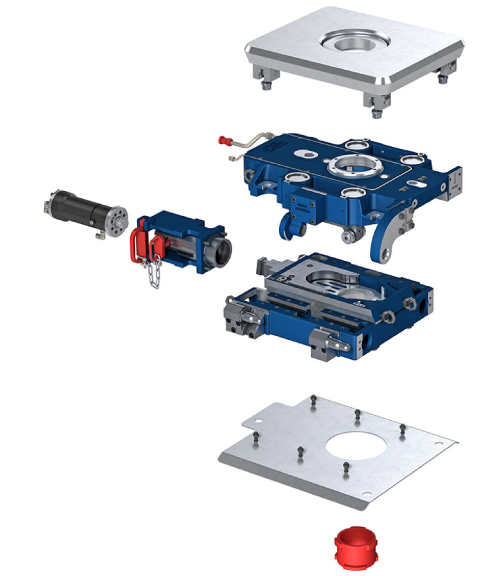

The mission of RHI Magnesita is to best support our customers in making steel production safe and economic while complying with the highest quality standards. In order to achieve this goal RHI Magnesita is following a modular scope of supply, centred around our core business of systems engineering. For SX ladle gate system, INTERSTOP® offers solutions at the ladle preparation area.

The full package contains following points:

The mission of RHI Magnesita is to best support our customers in making steel production safe and economic while complying with the highest quality standards. In order to achieve this goal RHI Magnesita is following a modular scope of supply, centred around our core business of systems engineering. For SX ladle gate system, INTERSTOP® offers solutions at the ladle preparation area.

The full package contains following points:

An expert dedicated to your area will get in touch with you.

If you have any questions, do not hesitate to contact us.