对不起,此内容只适用于English。 For the sake of viewer convenience, the content is shown below in the alternative language. You may click the link to switch the active language.

Tap-holes are a sensible part within the metal tapping process: Lots of unsafe manual handling work, lack of real and accurate flow control, as well as often decreased output through metal or slag remaining in the furnace. With our INTERSTOP® Slide Gates you can overcome these challenges: As integrated tapping solutions they yield optimal results with any furnace type.

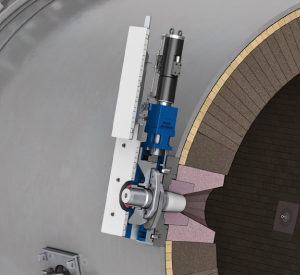

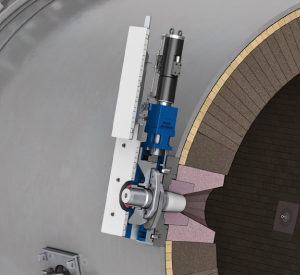

Slide gate for metal tapping

COP FLOW Slide Gate system for metal tapping is suitable for the following furnace types:

- Anode furnaces

- Holding furnaces

- Slag cleaning furnaces

- Converting furnaces

- Smelting furnaces

- Ladles

- Casting devices

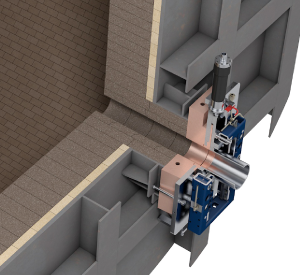

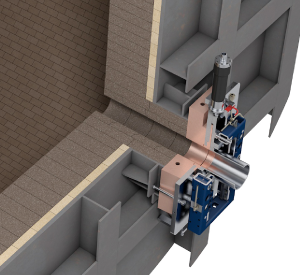

Slide gate for slag tapping

S-TAP Slide Gate system for slag tapping is suitable for the following furnace types:

- Slag cleaning furnaces

- Smelting furnaces

- Converting furnaces

- Refining furnaces

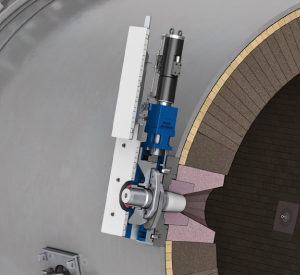

Slide gate for metal tapping

COP FLOW Slide Gate system for metal tapping is suitable for the following furnace types:

- Anode furnaces

- Holding furnaces

- Slag cleaning furnaces

- Converting furnaces

- Smelting furnaces

- Ladles

- Casting devices

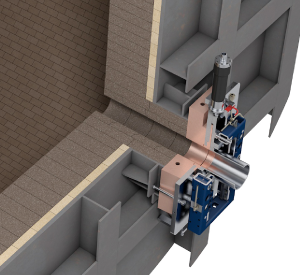

Slide gate for slag tapping

S-TAP Slide Gate system for slag tapping is suitable for the following furnace types:

- Slag cleaning furnaces

- Smelting furnaces

- Converting furnaces

- Refining furnaces