Adress: Bösch 83A

Location: 6331 Hünenberg

Phone: 041 785 75 00

Today’s requirements in the steel industry are moving towards flexible production programs and high productivity at the lowest possible cost. Reliable control of steel flow followed by extended refractory longevity and increased flexibility are of particular relevance.

The basic system philosophy of Interstop consists of enabling the respective operators to perform their tasks while taking into account their work safety and highest process safety.

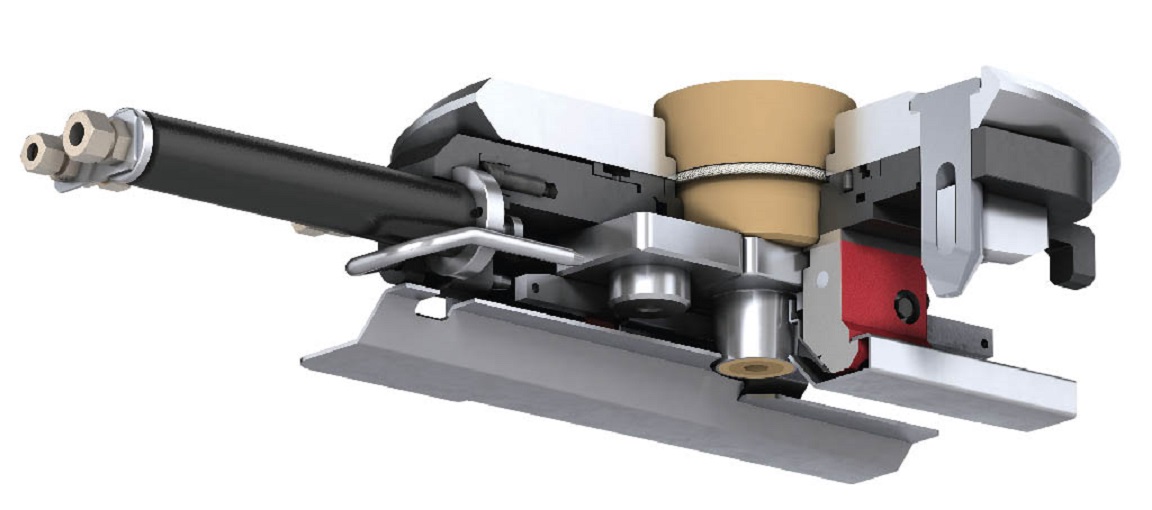

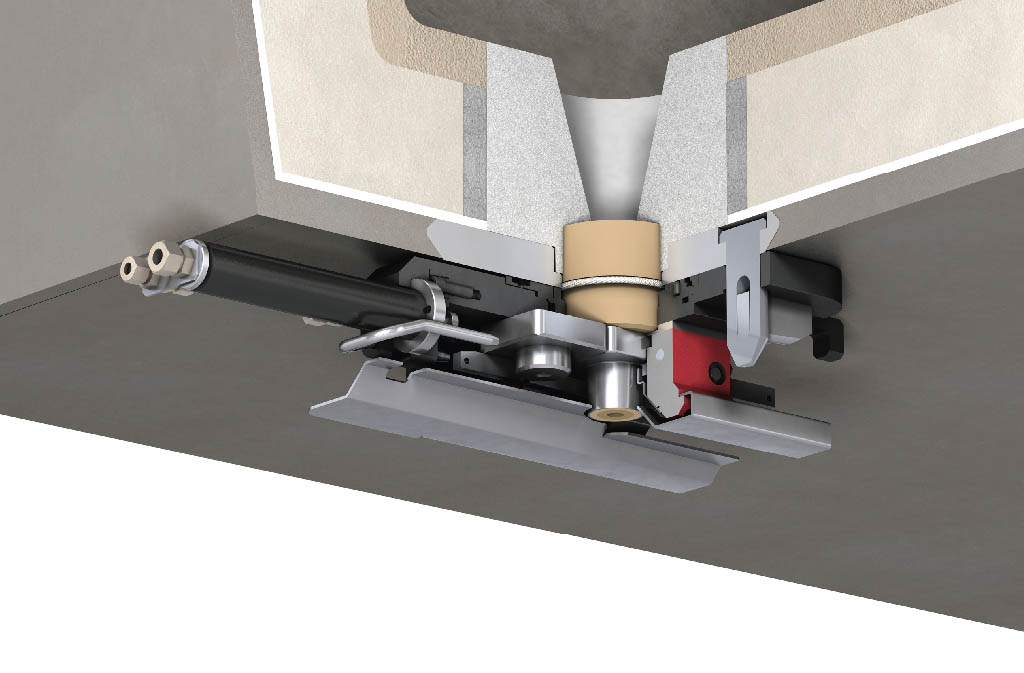

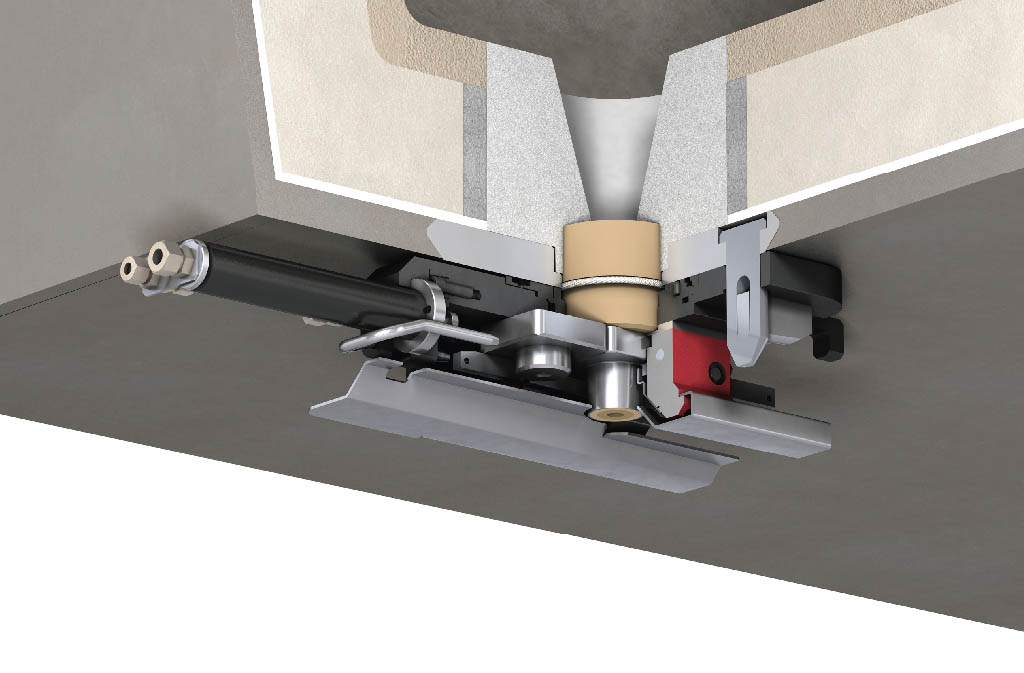

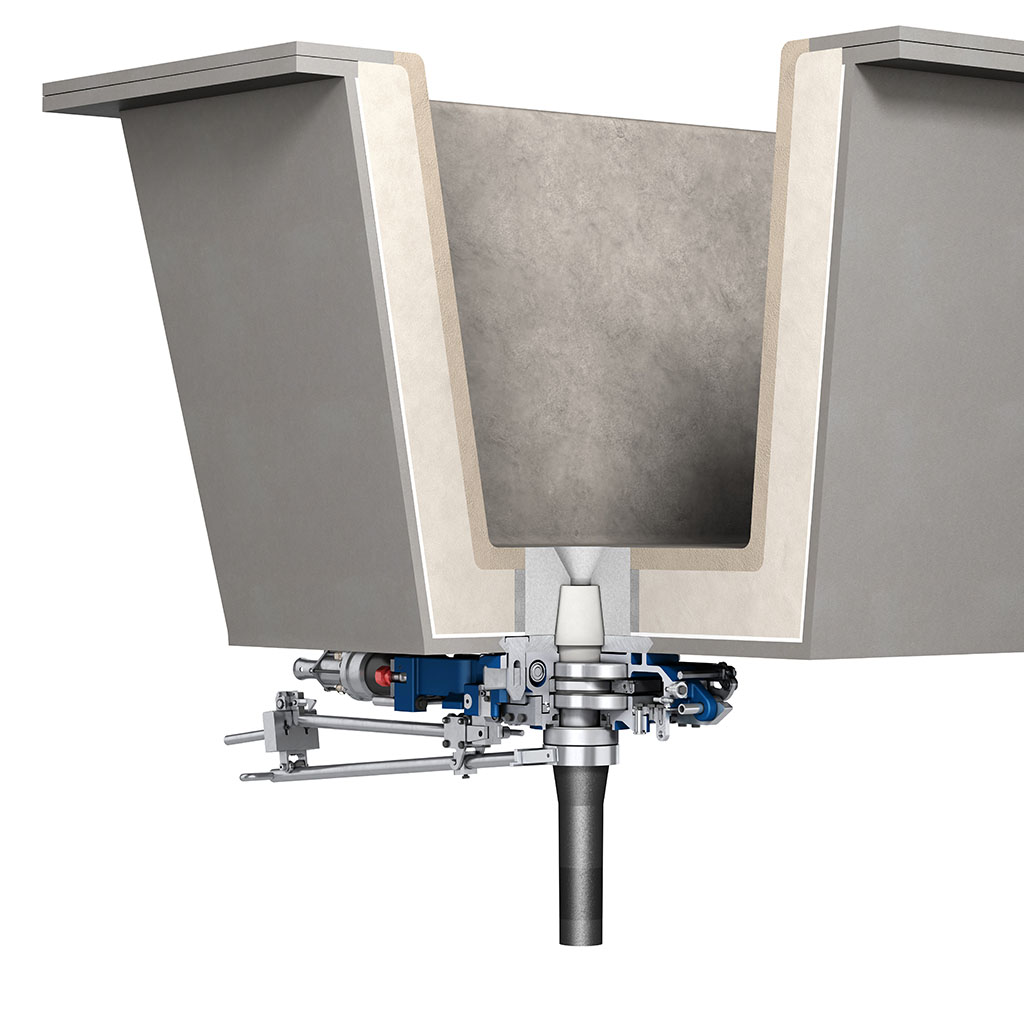

Our metering nozzle changer type INTERSTOP® MNC-AS convinces with an unobstructed view of the nozzle and the mold, compact dimensions, a mechanical fixation of the upper nozzle as well as well protected springs for a long service life. Designed for reliable and safe long sequence casting, the MNC-AS is your optimal product to take your operations to the next level.

In addition, the pressed and fired top nozzle are designed for long sequences.

Click to play the video and catch a glimpse of our Metering Nozzle Changer INTERSTOP® MNC-S.

Our metering nozzle changer type INTERSTOP® MNC-AS convinces with an unobstructed view of the nozzle and the mold, compact dimensions, a mechanical fixation of the upper nozzle as well as well protected springs for a long service life. Designed for reliable and safe long sequence casting, the MNC-AS is your optimal product to take your operations to the next level.

In addition, the pressed and fired top nozzle are designed for long sequences.

Click to play the video and catch a glimpse of our Metering Nozzle Changer INTERSTOP® MNC-S.

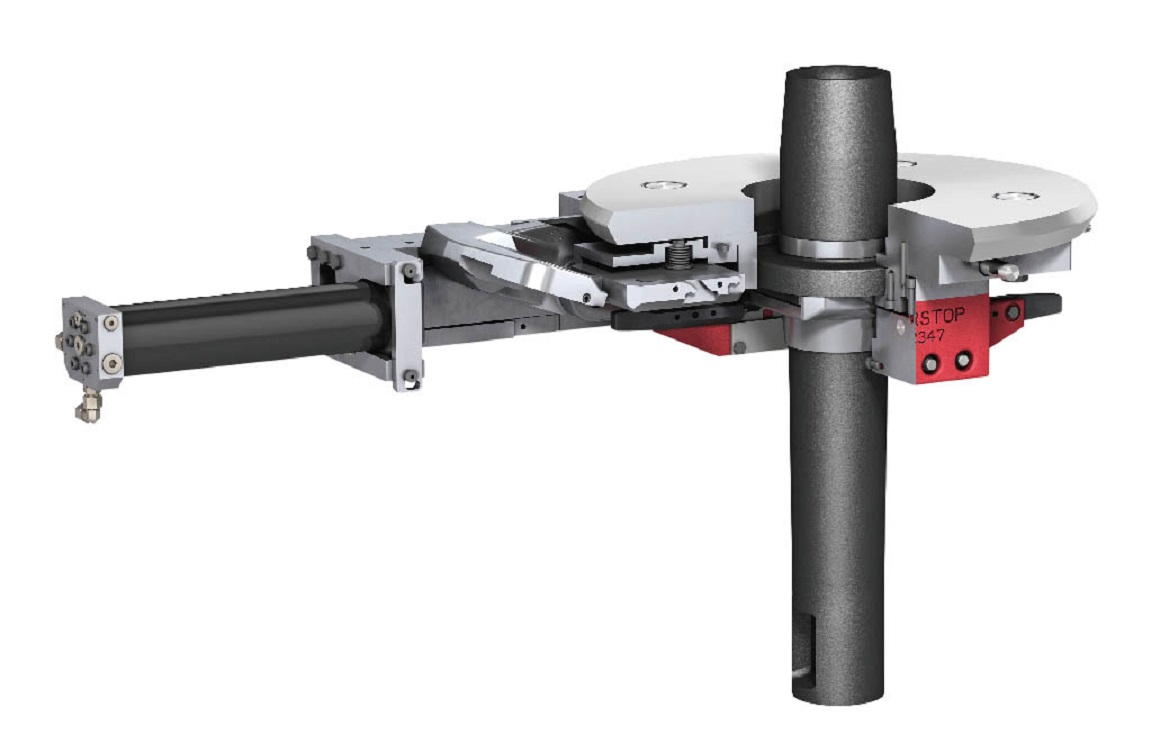

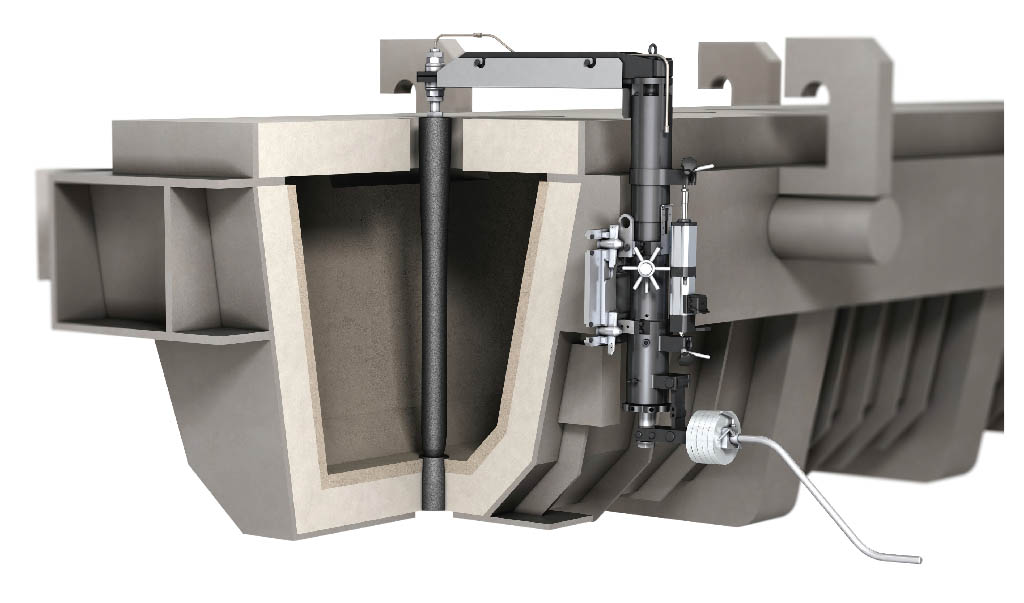

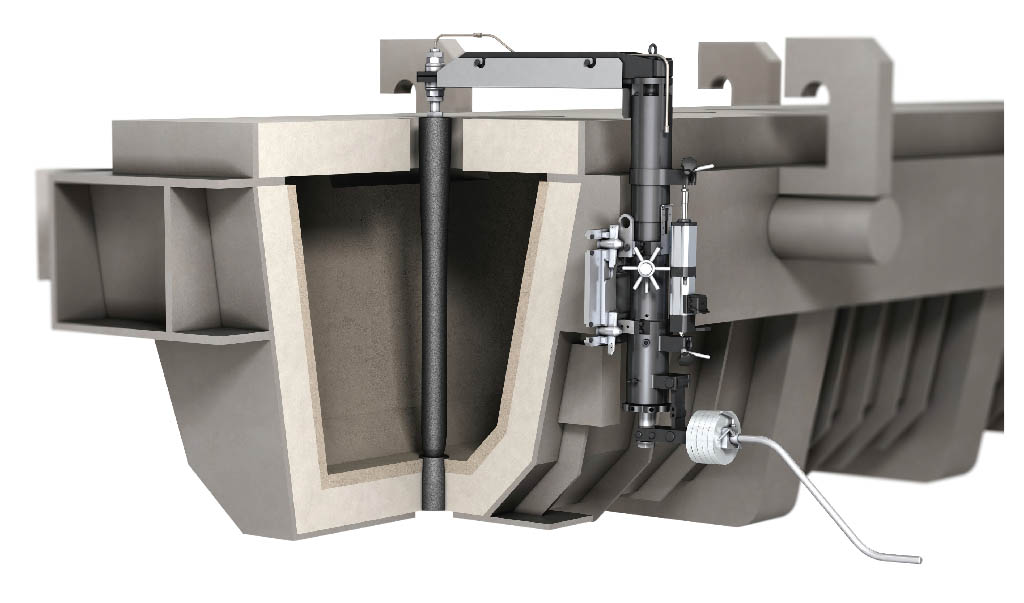

The INTERSTOP® Mono Tube Changer does not require handling of the blind plate. The nozzle design allows for improved handling and flow geometry, which supports clean steel production and automation. As an integral part of the system, the safety plate is always in a stand-by position and no manipulation of the cylinder is required.

Since the hydraulic cylinder is out of direct heat exposure, operators are exposed to minimal mold exposure time.

On top of that, the open front and side view into the mold allows for easier inspection.

Click to see our Mono Tube Changer INTERSTOP INTERSTOP® MTC-ESP in action.

The INTERSTOP® Mono Tube Changer does not require handling of the blind plate. The nozzle design allows for improved handling and flow geometry, which supports clean steel production and automation. As an integral part of the system, the safety plate is always in a stand-by position and no manipulation of the cylinder is required.

Since the hydraulic cylinder is out of direct heat exposure, operators are exposed to minimal mold exposure time.

On top of that, the open front and side view into the mold allows for easier inspection.

Click to see our Mono Tube Changer INTERSTOP INTERSTOP® MSC-ESP in action.

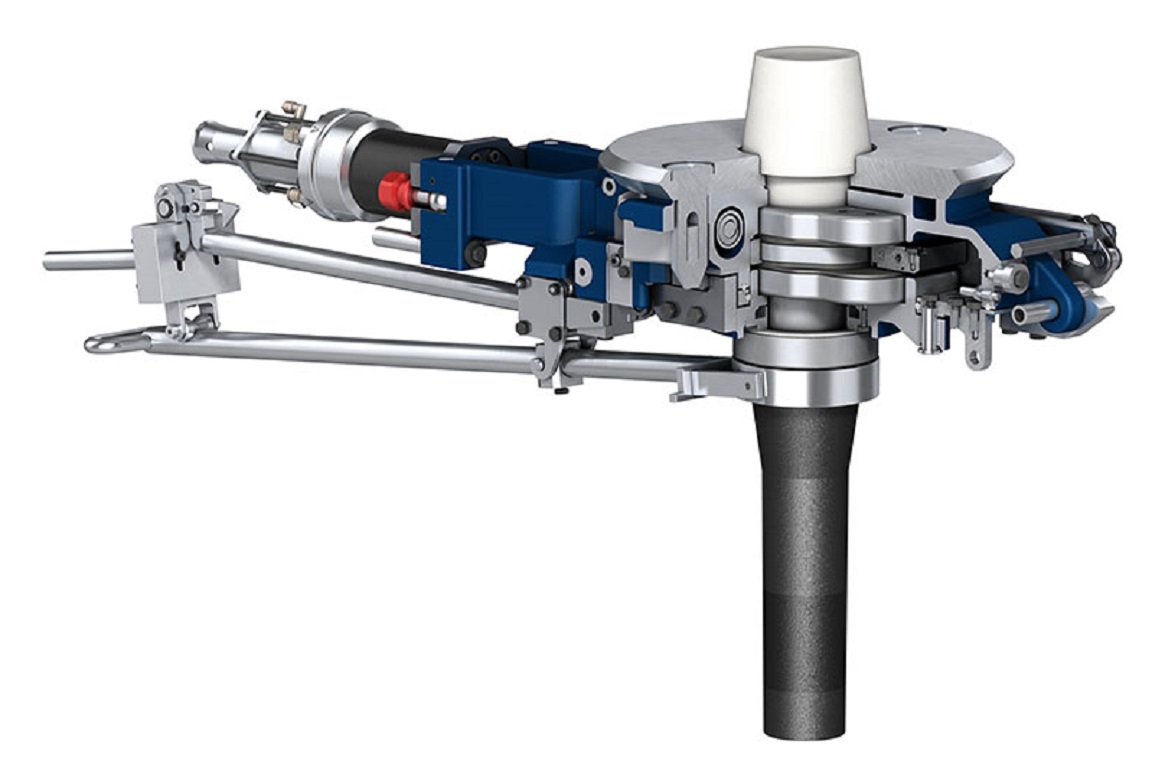

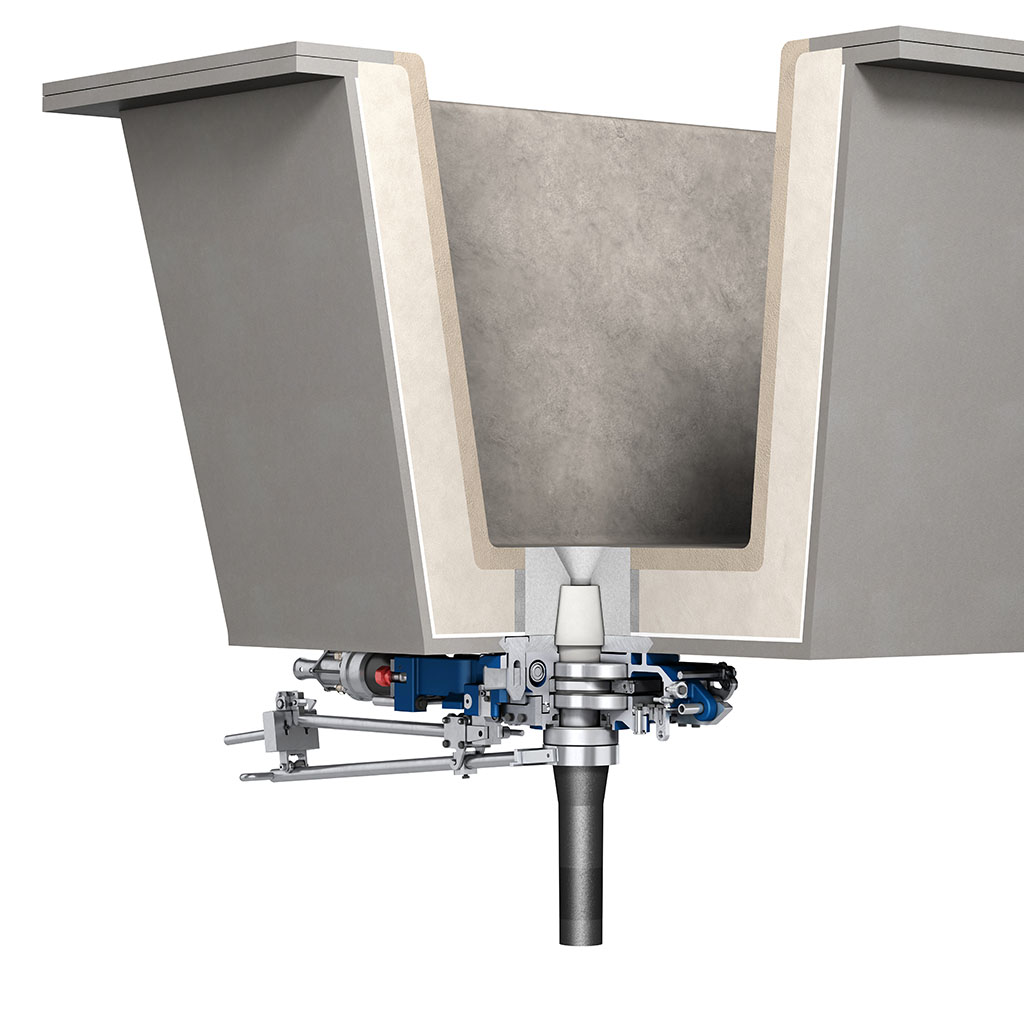

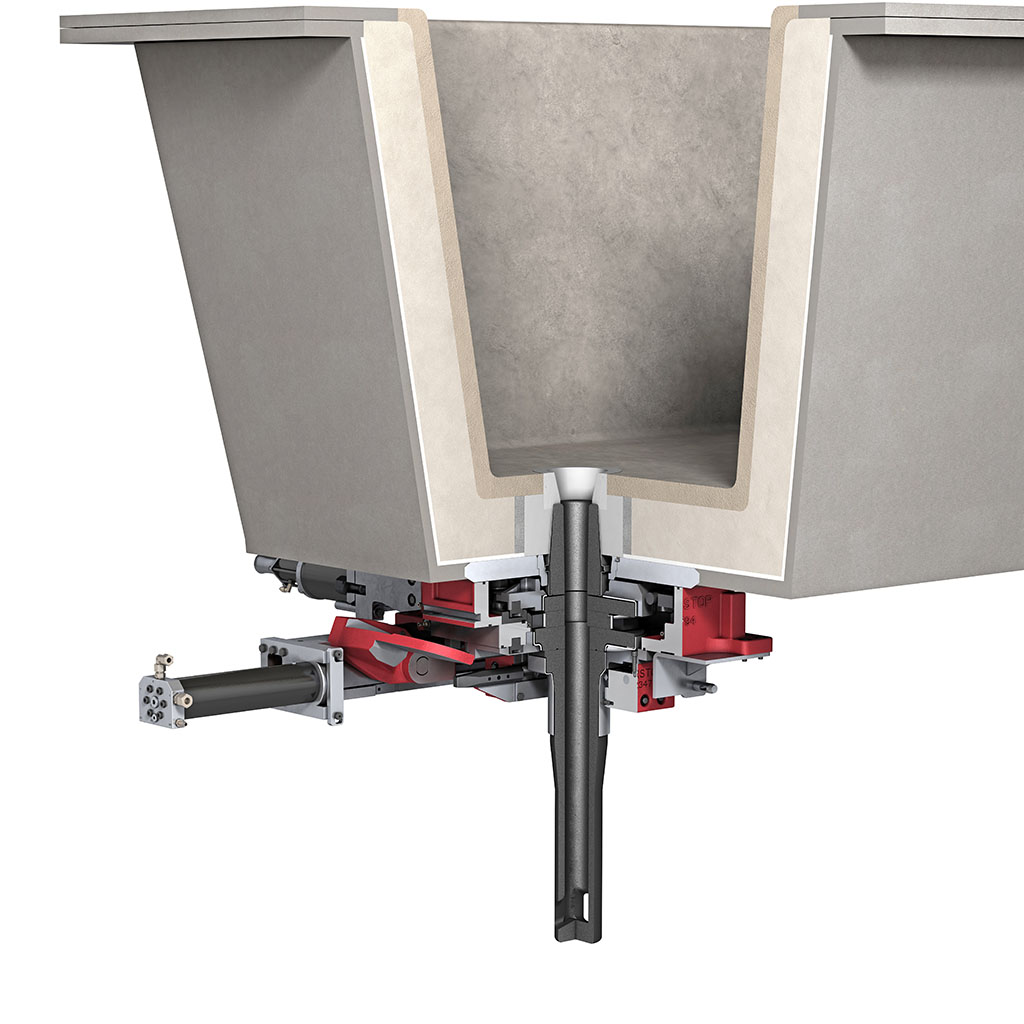

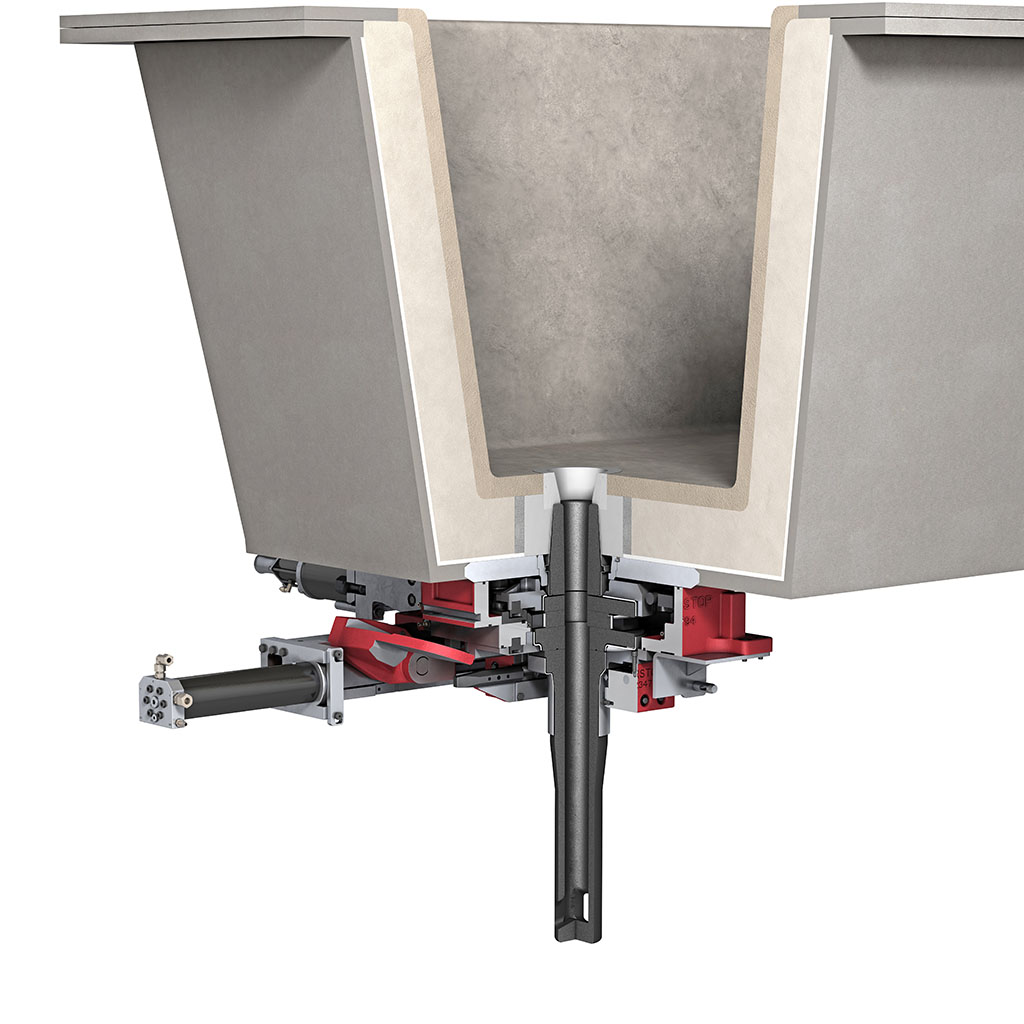

Looking for a high-precision tundish stopper mechanism for accurate flow control? The Stopper Rod Mechamism INTERSTOP®SRM-T enables easy installation and operation and provides an integrated solution for accurate mold level control.

Features of the systems include a high-precision stopper rod mechanism, electrically or hydraulically driven actuators, and the permanent option of manual intervention.

Looking for a high-precision tundish stopper mechanism for accurate flow control? The Stopper Rod Mechamism INTERSTOP®SRM-T enables easy installation and operation and provides an integrated solution for accurate mold level control.

Features of the systems include a high-precision stopper rod mechanism, electrically or hydraulically driven actuators, and the permanent option of manual intervention.

The closed box design of our Sealed Tundish Gate INTERSTOP® STG13 ensures safe inert gas containment of the refractory plates. An exact drive cylinder with integrated stroke measuring system and play compensation as well as a compact and modular design, which allows customized refractory assemblies, characterize this solution.

Moreover, this 3-plate tundish sealed solution is fully compatible with open and closed casting systems such as INTERSTOP MNC, 13QC and EG115.

The closed box design of our Sealed Tundish Gate INTERSTOP® STG13 ensures safe inert gas containment of the refractory plates. An exact drive cylinder with integrated stroke measuring system and play compensation as well as a compact and modular design, which allows customized refractory assemblies, characterize this solution.

Moreover, this 3-plate tundish sealed solution is fully compatible with open and closed casting systems such as INTERSTOP MNC, 13QC and EG115.

The INTERSTOP® STG33 Sealed Tundish Gate not only offers a sealed system concept and compact design, but also includes a inert gas application on the housing, tundish nozzle and refractory joints and a minimized number of components.

This innovative solution is rounded off by automatic start-up, automatic mold level control, automatic emergency functions and precise steel flow control.

The INTERSTOP® STG33 Sealed Tundish Gate not only offers a sealed system concept and compact design, but also includes a inert gas application on the housing, tundish nozzle and refractory joints and a minimized number of components.

This innovative solution is rounded off by automatic start-up, automatic mold level control, automatic emergency functions and precise steel flow control.

If you have any questions regarding our company or our solutions,

please do not hesitate to contact us. An expert will contact you

in the shortest possible time.