- About

- Solutions

- Governance

- Investors

- Sustainability

- Sustainability

- Newsroom

- Jobs

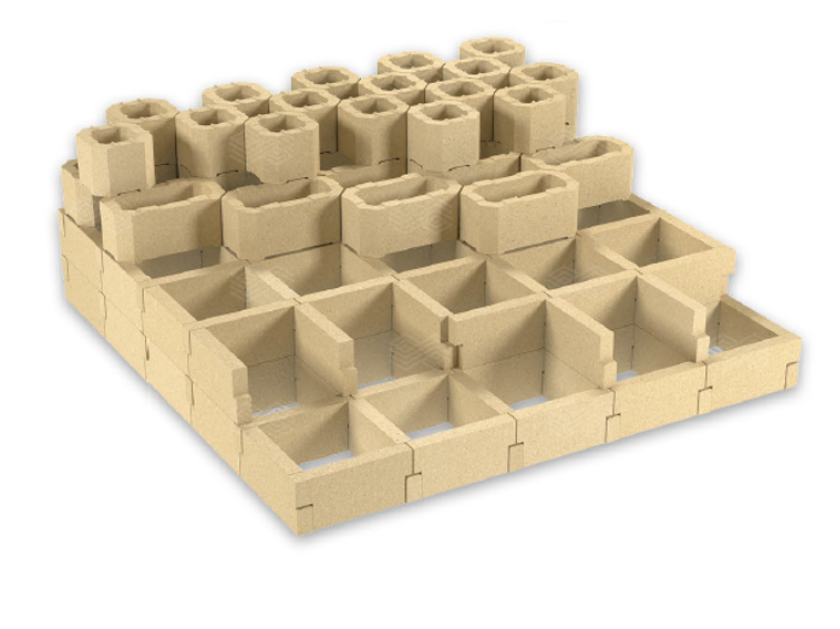

The glass melting process requires large amounts of energy at high process temperatures – posing challenges in terms of emissions, refractory lifetime and mechanical stability. To use energy as efficiently as possible, regenerators have become a standard for heat recovery. Our INNOREG – Innovative Regenerator tackles all those challenges with one system, using optimal checker shapes and materials for highest possible stability while maximizing CO2 reduction and refractory lifetime.

Energy saving and high thermal efficiency are the basic requirements for CO2 emission reductions.

An appropriate material selection and optimized design, including the checkerwork shapes and regenerator casing are aimed to achieve the highest thermal efficiency, directly related to the highest combustion air preheating temperatures.

An improvement of 2% in the thermal efficiency means approx. 30°C increase of combustion air preheating temperature, which has a direct impact on the furnace fuel consumptions.

INNOREG – Innovative Regenerator is a toolbox providing you great benefits:

incl. checkerwork, transition tiles and rider arches, casing (crown and wall)

Download our INNOREG folder and learn more about our capabilities!

Our plants of Mainzlar and Radenthein in Europe, Contagem in Brasil , Clasil and Rajgangpur in India and Dalian in China, ensure that we can provide you great availability, fast delivery times and high production capacities. Our experienced team is ready to support you in the accurate design of your INNOREG system – tailored to your individual specifications. Upon receiving the project data our team will provide you an accurate calculation of the thermal profile and assist you in the selection of the suitable materials and shapes.

We have introduced a large variety of shapes to meet the requirements of different operating conditions, while maintaining a high thermal efficiency