Limited heat numbers from EAF campaigns, high costs from EAF downtime, and a challenging work environment for your employees: all these challenges are present in your steel mill on a regular basis.

To counteract these aspects, we have developed a gunning manipulator for highly efficient gunning repair of any part of the EAF: the Terminator XL!

TERMINATOR S

|

TERMINATOR XL

|

|

Basic Model with Manual Gunning Mode and a possibility to upgrade to Automatic Guided Gunning Mode.

|

Basic Model with additional laser scanner for residual refractory lining measurement with Automatic Guided Gunning.

|

The Automatic Guided Gunning Mode simplifies handling and increases safety for the operator. In addition, it saves time with pre-defined gunning programs and applies your material optimally.

Basic Model with Manual Gunning Mode and a possibility to upgrade to Automatic Guided Gunning Mode.

Basic Model with additional laser scanner for residual refractory lining measurement with Automatic Guided Gunning.

![]()

The Automatic Guided Gunning Mode simplifies handling and increases safety for the operator. In addition, it saves time with pre-defined gunning programs and applies your material optimally.

Discover in 4 easy steps how the Terminator XL’s operating model can optimize your gunning process.

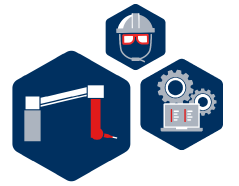

Scanning can be performed via remote control or on the visualization. The laser scanner measures residual refractory lining thickness.

Views with residual refractory lining thickness are displayed on the visualization PC over the laser software. Images are available in form of 2D & 3D images and results can be analyzed.

Import your wall contour view into the Terminator XL software. You can select gunning areas and number of layers manually or import pre-defined gunning programs. Refractory gunning mix consumption and required time are pre-calculated before gunning.

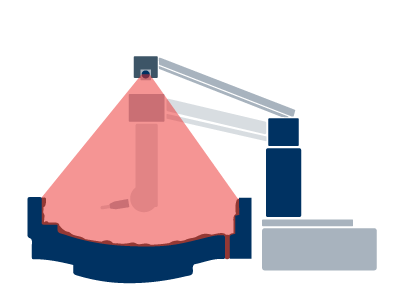

Terminator XL boom is positioned in the center of the furnace by means of radio remote control. Pre-selected areas are gunned automatically. Gunning consumption data and process data are stored, and can be analyzed*.

*ANKERJET A enables data transfer.

Scanning can be performed via remote control or on the visualization. The laser scanner measures residual refractory lining thickness.

Views with residual refractory lining thickness are displayed on the visualization PC over the laser software. Images are available in form of 2D & 3D images and results can be analyzed.

Import your wall contour view into the Terminator XL software. You can select gunning areas and number of layers manually or import pre-defined gunning programs. Refractory gunning mix consumption and required time are pre-calculated before gunning.

Terminator XL boom is positioned in the center of the furnace by means of radio remote control. Pre-selected areas are gunned automatically. Gunning consumption data and process data are stored, and can be analyzed*.

*ANKERJET A enables data transfer.

Please select your local sales office below.

An expert dedicated to your area will get in touch with you.

RHI Magnesita

Refractory Application Machinery – West Asia, India & Africa