Adress: Bösch 83A

Location: 6331 Hünenberg

Phone: 041 785 75 00

The operation of flow control systems has so far required the physical presence of personnel on the CCM floor and in the ladle preparation area. Besides the steel-filled vessels and the exposure to thermal radiation, the working environment for the operators is, on the one hand, dangerous and, on the other hand, the physical stresses to be overcome are associated with a high level of exertion.

To overcome this, as well as to take the steel industry to a new level of stability and safety, INTERSTOP® is continuously working on innovative automation, robotics, and digitalization solutions.

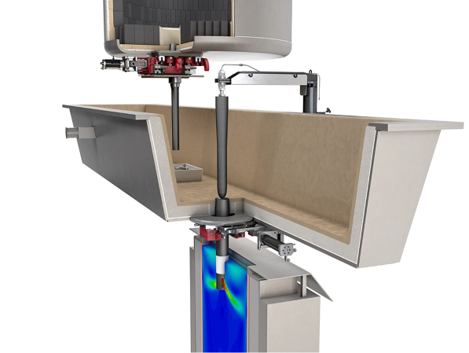

This fully automatic tundish level control solution allows a smooth switching from Manual to Auto-Mode, offers a control software to minimize gate movement stroke as well as intelligent internal system failure tracking and an alarm display. Further, this solution is ready to operate with a slag detection system and comprises a fully independent operating (fail-safe) emergency close system. The TLC is designed for remote access and a key component of our Health Check Platform.

This fully automatic tundish level control solution allows a smooth switching from Manual to Auto-Mode, offers a control software to minimize gate movement stroke as well as intelligent internal system failure tracking and an alarm display. Further, this solution is ready to operate with a slag detection system and comprises a fully independent operating (fail-safe) emergency close system. The TLC is designed for remote access and a key component of our Health Check Platform.

Our fully automatic mould level control (MLC) solution with overflow protection and breakout detection for automatically close of slide gate includes a visualization system for trending, alarm messages and parameter setting. A special feature of our fully integrated INTERSTOP solution is the very high accuracy of +/- 2mm. The MLC is designed for remote access and online support.

Our fully automatic mould level control (MLC) solution with overflow protection and breakout detection for automatically close of slide gate includes a visualization system for trending, alarm messages and parameter setting. A special feature of our fully integrated INTERSTOP solution is the very high accuracy of +/- 2mm. The MLC is designed for remote access and online support.

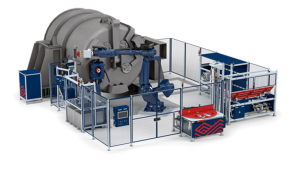

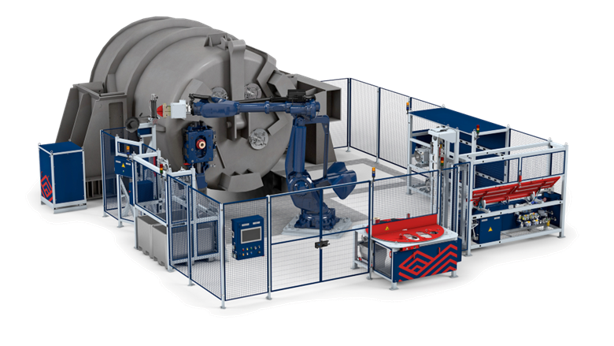

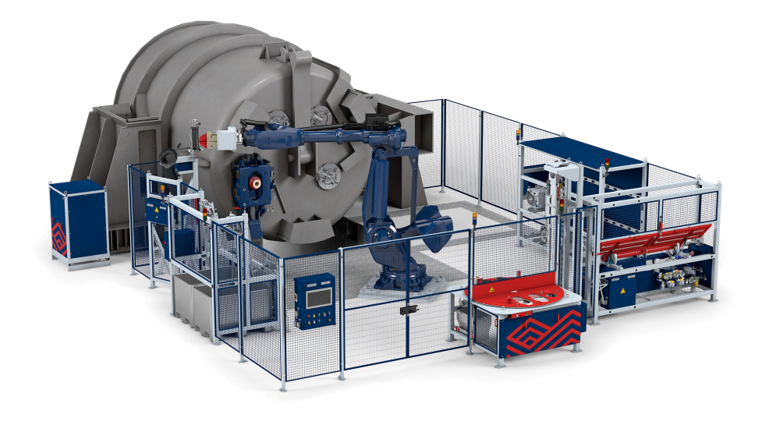

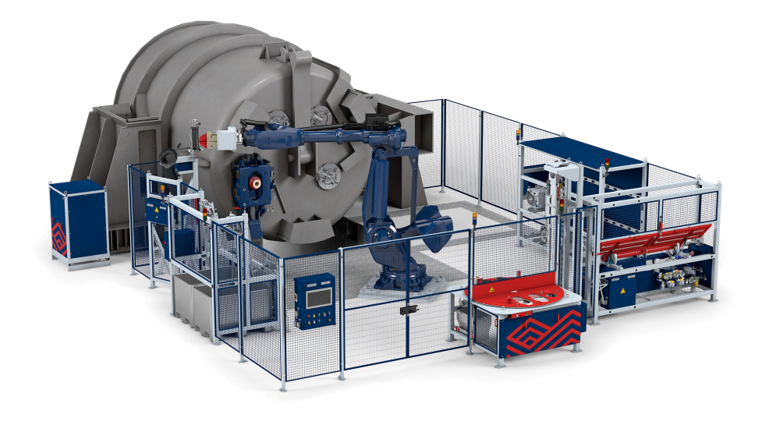

The robotic solution for the fully automated ladle preparation area (LPA) provides operational safety. No operators are exposed to liquid steel, heat, dust, and time pressure. Higher process stability is achieved through improved reliability of the tasks performed. In addition, there is an extension of the refractory service life. An integral part of the LPA solution is the Health Check Platform providing predictive maintenance models based on data collection.

The robotic solution for the fully automated ladle preparation area (LPA) provides operational safety. No operators are exposed to liquid steel, heat, dust, and time pressure. Higher process stability is achieved through improved reliability of the tasks performed. In addition, there is an extension of the refractory service life. An integral part of the LPA solution is the Health Check Platform providing predictive maintenance models based on data collection.

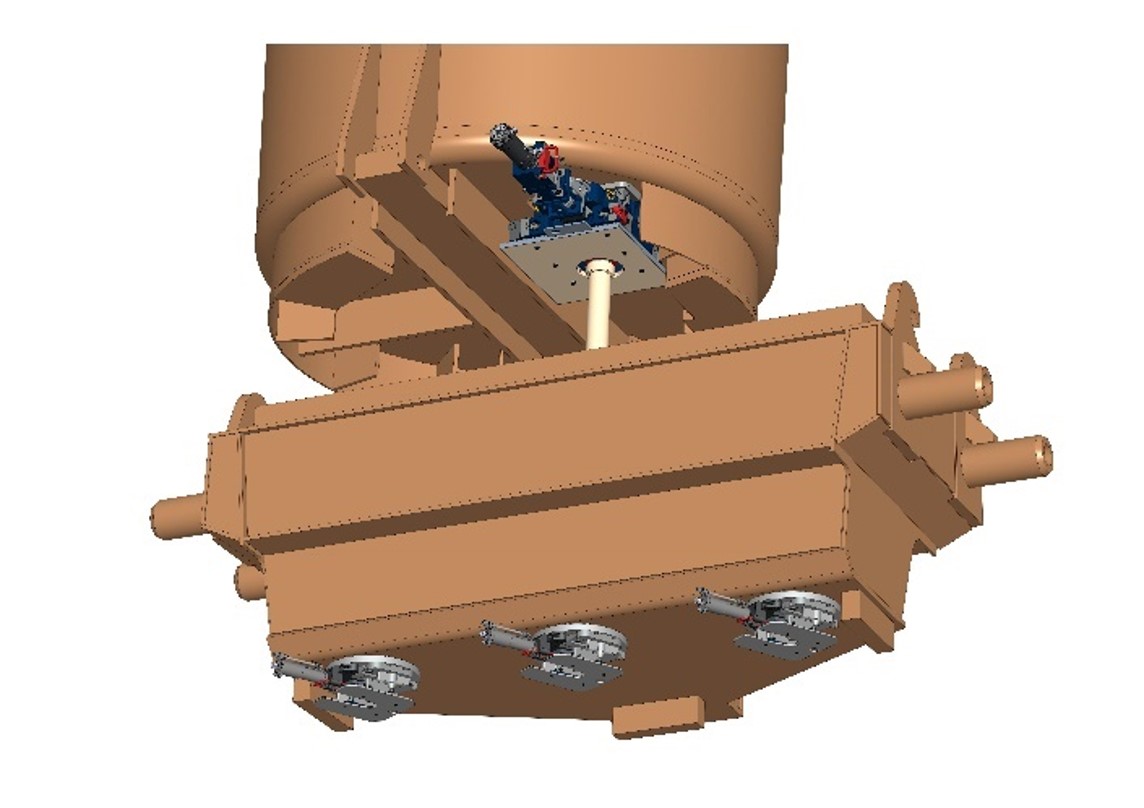

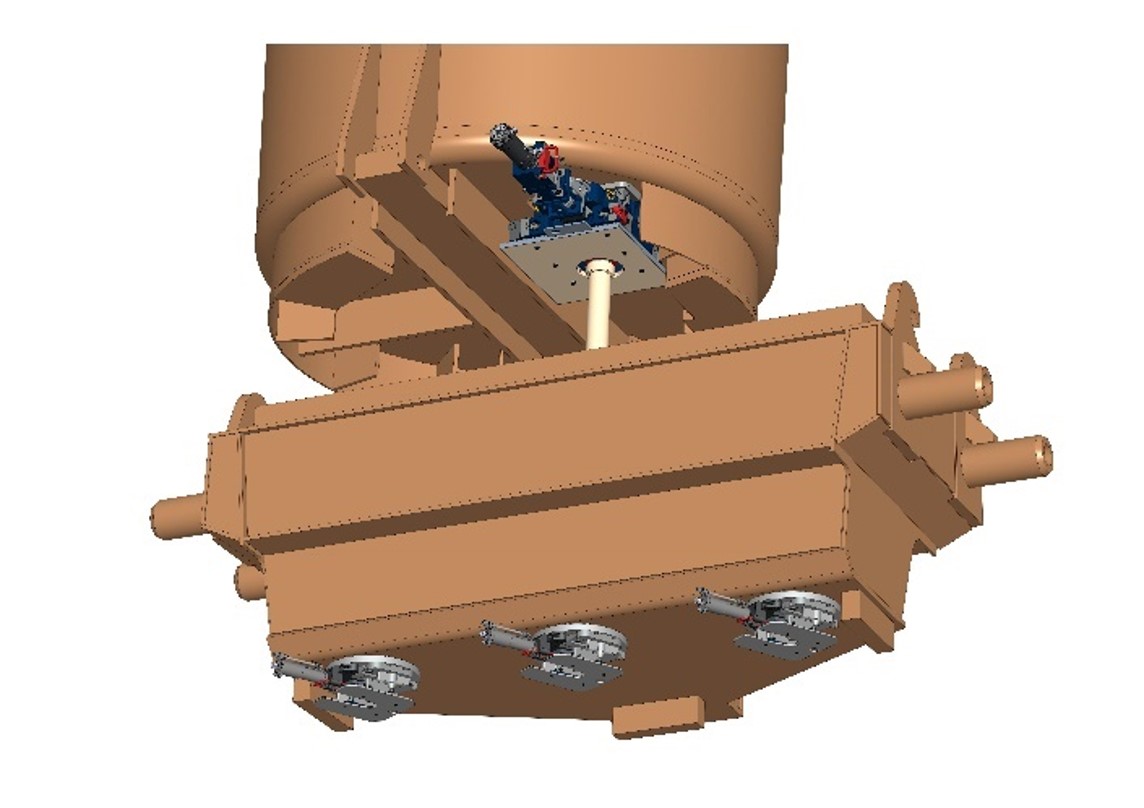

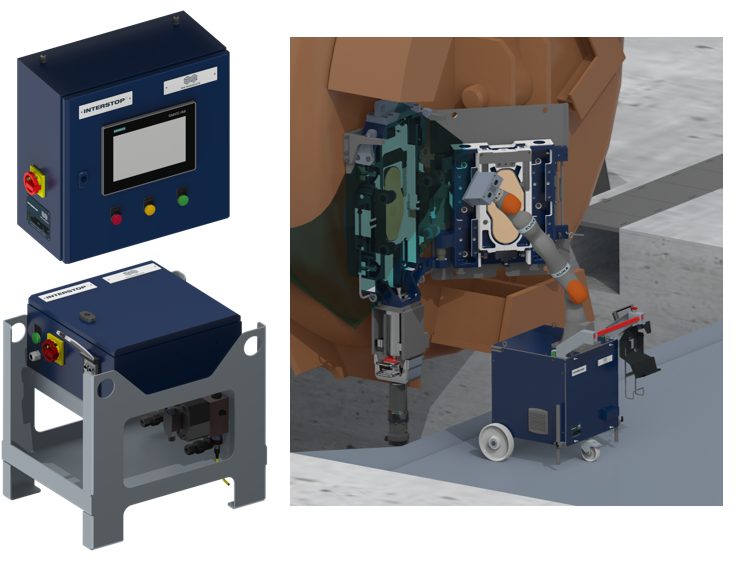

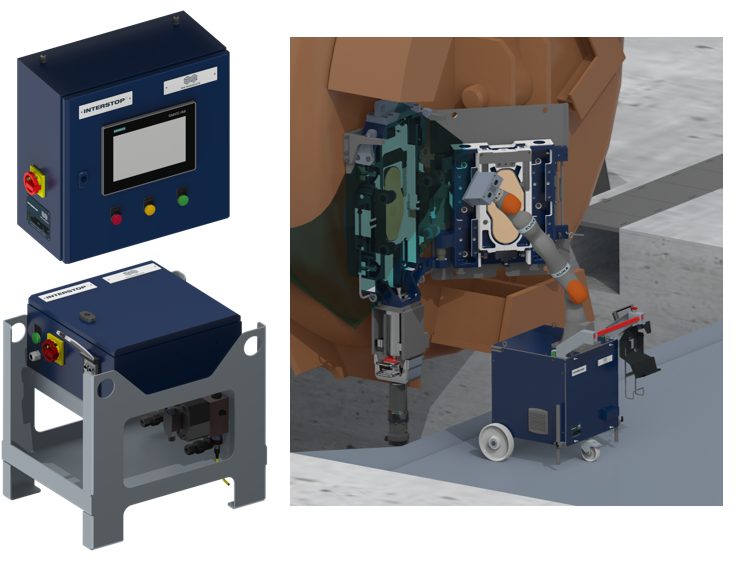

The optimized hydraulic cylinder with media coupling allows an easy one-step coupling process. Casting cylinder, sensor signals like slag detection and process gases are connected simultaneously. The cylinder with media coupling is intended to work with a robot, eliminating the need of operator presence in dangerous areas. When the MC is operated manually, it also increases operators’ safety and process stability.

The optimized hydraulic cylinder with media coupling allows an easy one-step coupling process. Casting cylinder, sensor signals like slag detection and process gases are connected simultaneously. The cylinder with media coupling is intended to work with a robot, eliminating the need of operator presence in dangerous areas. When the MC is operated manually, it also increases operators’ safety and process stability.

The fully automatic Monotube Change and powder feeding solution is an integrated solution that maximizes safety in the casting area. It is based on our automation-ready Monotube Changer MTC. Continuous powder feeding, compact dimensions, improved process control and efficiency are the hallmarks of this solution.

The fully automatic Monotube Change and powder feeding solution is an integrated solution that maximizes safety in the casting area. It is based on our automation-ready Monotube Changer MTC. Continuous powder feeding, compact dimensions, improved process control and efficiency are the hallmarks of this solution.

The health check platform introduces decision support to the flow control process by generating data from existing processes. The health check platform uses data from the hydraulic system to replace subjective decisions with machine-learning-based decision support. Additionally, a 3D geometry analysis of refractories with a high-performance camera system assesses the plate condition to make predictions. The predictive maintenance system helps to extend plate lifetimes even further.

The health check platform introduces decision support to the flow control process by generating data from existing processes. The health check platform uses data from the hydraulic system to replace subjective decisions with machine-learning-based decision support. Additionally, a 3D geometry analysis of refractories with a high-performance camera system assesses the plate condition to make predictions. The predictive maintenance system helps to extend plate lifetimes even further.

If you have any questions regarding our Automation and Robotics solutions,

please do not hesitate to contact us. An expert will contact you

in the shortest possible time.