Making the most of scarce resources, preserving the environment, and using energy in an efficient way are the megatrends of our times.

Controlled incineration processes under technically optimized circumstances provide one part of the answer.

Well-constructed boilers and modern power plants contribute valuable energy and give their share in an integrated approach to waste management.

Our Innovation approach is the best practice

We entrust our dedication to constantly find new and better solutions to existing problems of our Research and Development department and our Technical department.

Refractories are a crucial interface for many core industries, such as the production of iron, steel, cement, aluminum and other essential materials.

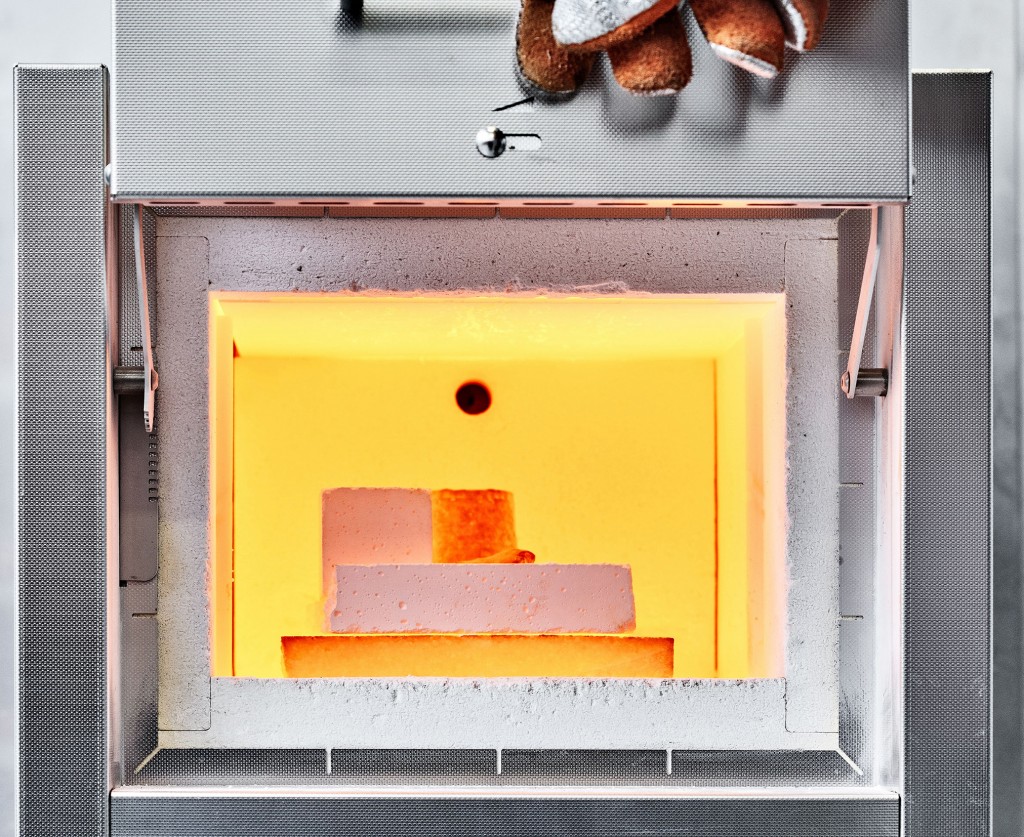

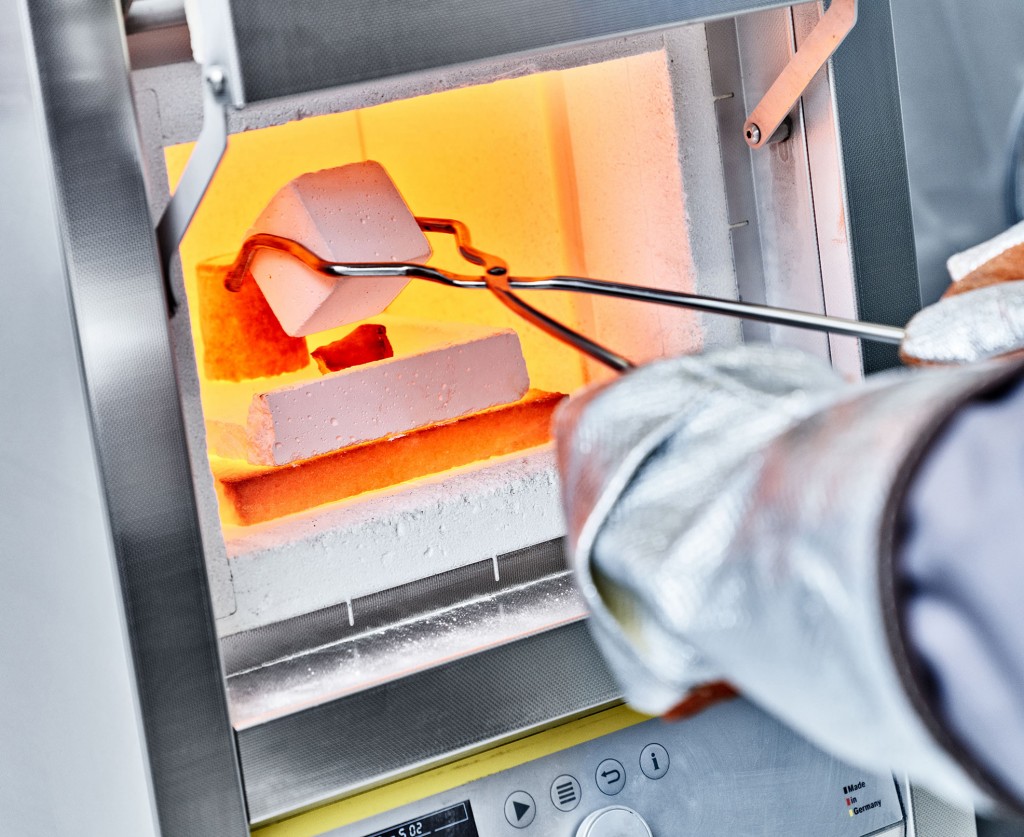

Our products are used in the most exposed areas of production. They are subject to a wide range of highly adverse conditions: extreme temperatures and sudden temperature changes, chemical attacks, abrasions, infiltrations and build-ups by potentially detrimental materials.

All our formulations, research and developing procedures are extremely precise, dedicate and challenging. The process starts with the QC control of all raw materials, it has to pass all our internal testing procedures. Has to be supported by internal and customer specific request, while during the application and installation step, we can identify a better solution for each kind of operation.

When we innovate, we consider a wide range of factors: economic, environmental, ergonomic, and others.

In addition, our unique taphole clay palette packaging is designed so that the operators on the casthouse can take each individually wrapped piece of product in an ergonomic way instead of having to bend down into a box.

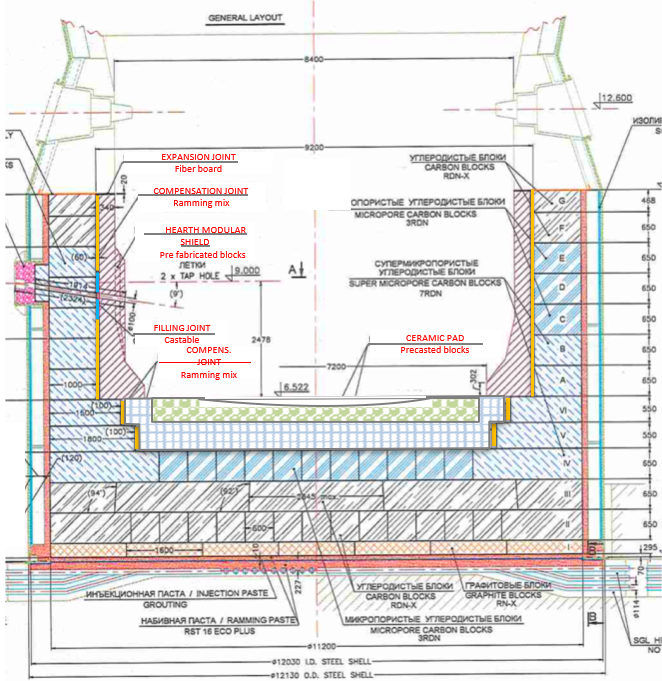

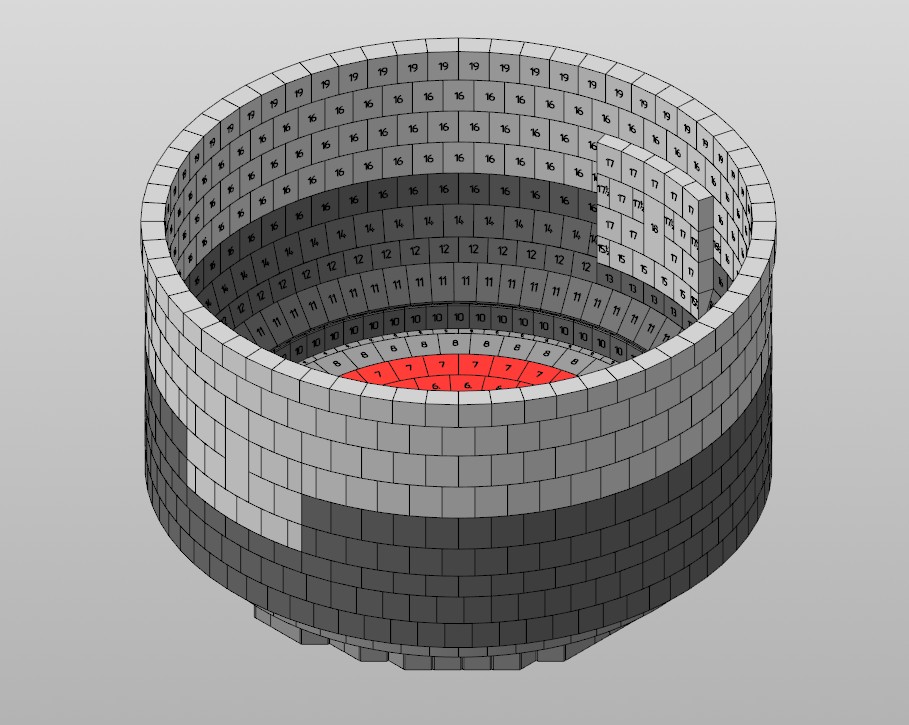

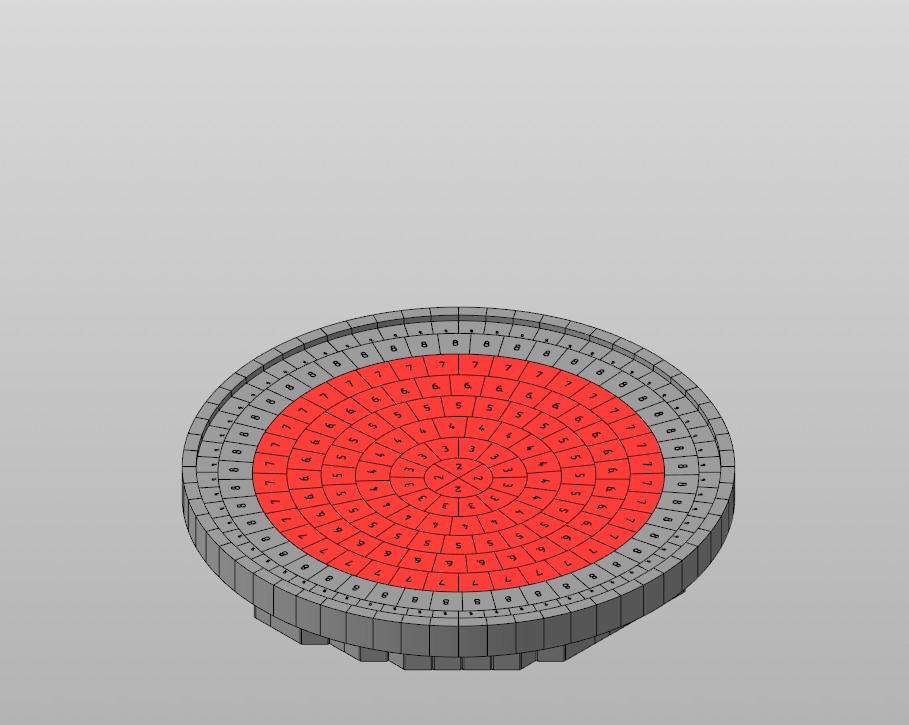

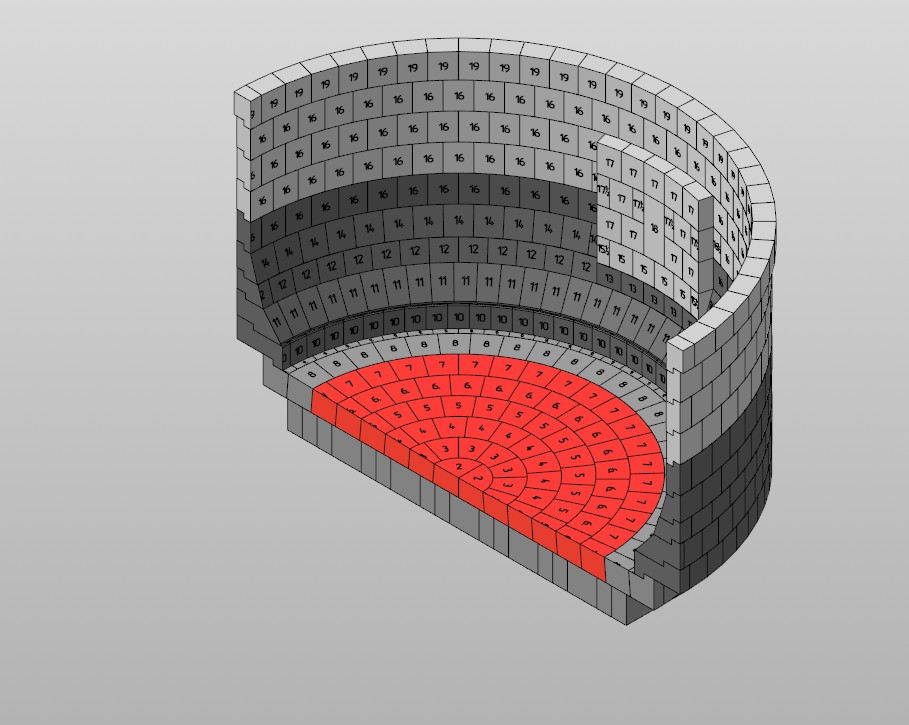

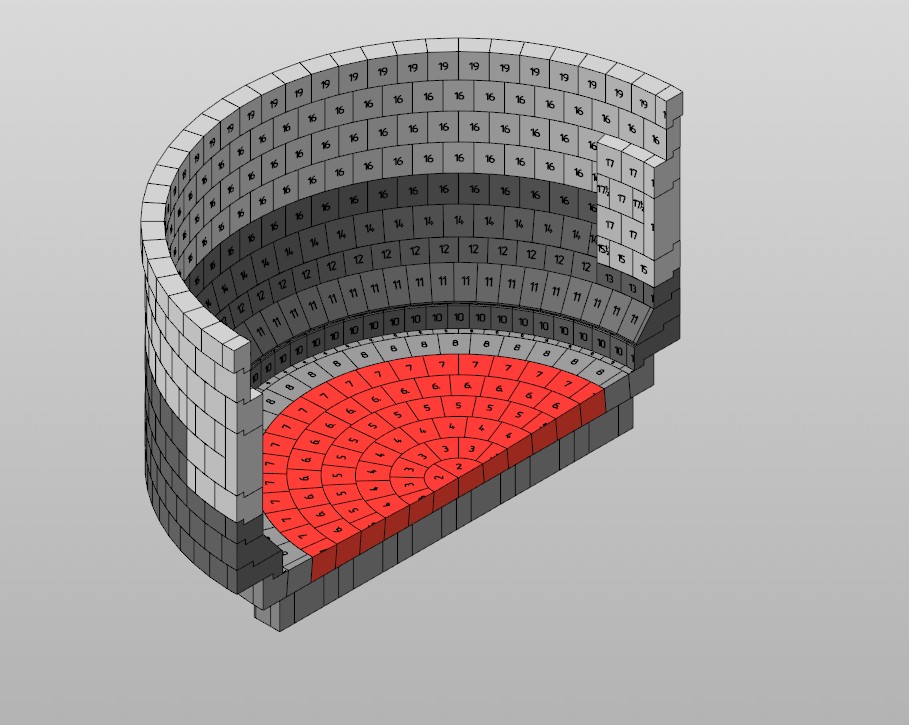

The Modular Hearth Shield (MHS) by Alumina Monolithic Solutions & Ironmaking offers products to create a protective long lasting layer for the carbon lining in the blast furnace hearth.

With this concept we offer an ideal geometrical solution based on optimal material quality, instead of liningfollowing a “just enough” approach.

Carbon lining protection, i.e. contrast the erosion mechanisms given by:

Material quality and geometrical solution overcome the concept “preshaped” lining.